Plant Structure*

(*Based on C Holland and W Kezar, The Pioneer Forage Manual — Nutritional Guide. Pioneer Hi-Bred International Inc. 1999.)

Stover

The defining characteristic of plant tissue, such as that comprising the stems and leaves of corn stover, is that it contains a large portion of cell-wall material. The amount and type of plant cell wall material determines the nutritional quality of the stover.

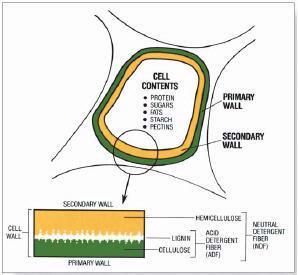

A young plant cell has a single outer layer referred to as the primary cell wall (Fig. 1). As the plant matures, a second cell wall is laid down on the inside of the first cell wall. This secondary wall is thicker than the primary wall, giving plant cells tensile strength. The primary and secondary cell walls combined make up 40-80% of the dry matter content of corn stover. The main structural components of both primary and secondary cell walls are two complex carbohydrates called cellulose and hemicellulose. Cellulose is one of the most abundant organic materials on earth. Animals cannot produce enzymes to digest cellulose or hemicellulose. However, the micro- organisms residing in the digestive tract of ruminants (primarily in the rumen) produce enzymes which efficiently digest and utilize cellulose.

Figure 1. Diagram of a plant cell showing cell-wall structure (from Advanced Forage Management, 1999).

With advancing maturity, forage cells insert a complex non-carbohydrate material known as lignin between the primary and secondary walls. Lignin gives the plants additional tensile strength and rigidity and can be thought of as the primary skeleton of the plant cell. Lignin is important from a nutritional perspective because it is totally indigestible and its presence reduces the availability of the cellulose and hemicellulose portions of the forage. The primary cell wall is like a layer of bricks, the secondary wall like a layer of cinder blocks laid inside the bricks and lignin is like mortar added later between the bricks and cinder blocks. As the corn plant advances in maturity, more lignin is added making the cell walls more difficult to digest.

Grain

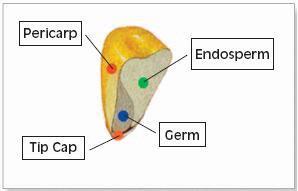

A corn kernel is largely comprised of three parts: the pericarp (outer coating or hull), the endosperm, and the germ (or embyro) as shown in Fig. 2.

Figure 2. Parts of a corn kernel

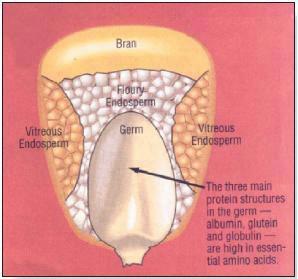

The pericarp or hull of the corn kernel is a thin outer covering made up of two layers. Removal of this part of the corn kernel results in corn bran, commonly used for cooking. The endosperm, which comprises up to 82% of the kernel’s dry weight, is the source of energy for the germinating seed. In all field corn, the endosperm is comprised of two types of starch: vitreous and floury (Fig. 3). The proportion of these starches is controlled genetically. The floury endosperm is the softer starch, and as the kernel matures, this type of starch dries down to create the “dent” in the top of the kernel of dent varieties. Vitreous starch, more abundant in flint corns, tends to be harder for cows to digest because the starch granules are embedded in a dense protein matrix. Therefore, as the amount of vitreous starch present in corn kernels increases, total tract starch digestibility decreases, unless the silage is ‘processed’ (see Corn Silage Processing section).

Figure 3. Types and placement of starch within the corn kernel (from Dairy Herd Management Vol. 35 No.11, Nov. 1998).

The germ of the kernel contains all the genetic information, some nutrients, and oil needed to enable germination and early growth. The germ is comprised of 25% fat (corn oil) which is high in linoleic acid (see Fats in Corn Silage section). The tip cap is not covered by the pericarp as it is the attachment point between the kernel and the cob.

Assessment of corn silage quality*

(*Based on C Holland and W Kezar, The Pioneer Forage Manual — Nutritional Guide. Pioneer Hi-Bred International Inc. 1999.)

What is ‘Detergent’ Fibre?

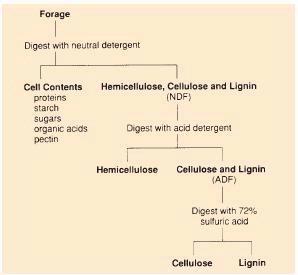

The ‘detergent-fibre’ method for assessing quality of forages was introduced about 1970. The earlier crude fibre system failed to generate accurate estimates of digestible nutrients over a wide range of forages; it tended to underestimate good quality forages and overestimate poor quality forages. The detergent system of forage analysis is now the most common way to assess forage quality. Fig. 4 shows a schematic of the detergent system of forage analysis. Detergent analyses are performed on dried and finely ground samples.

Figure 4. The detergent (Van Soest) procedure to partition forage fractions.

Neutral Detergent Fibre (NDF)

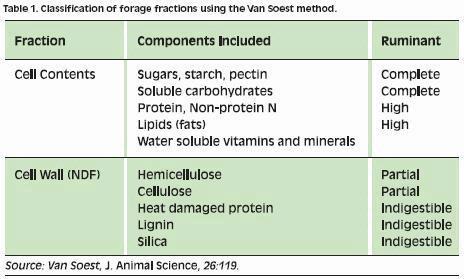

For determining NDF, samples are boiled in a special detergent at a neutral pH of 7.0, then filtered. The soluble portion that passes through the filter contains highly digestible nutrients which were contained within the cells (see Table 1). The insoluble portion of the forage that does not pass through the filter is called the ‘neutral detergent fibre’. This fraction contains the cell wall material including cellulose, hemicellulose, lignin and silica (Table 1). The proportion of NDF in corn stover increases with the advancing maturity of corn. In recent years, seed companies have been developing hybrids for silage production where increasing maturity does not necessarily result in decreasing fibre digestibility.

On a simple level, neutral detergent fibre is sometimes used as a (negative) indicator of feed intake. As the NDF increases, animals tend to consume less forage. The relationship between NDF and intake is:

Feed intake (dry matter) as percent of body weight = 120/NDF(%)

Example: corn silage with an NDF value of 40% will be consumed at 120/40=3% of body weight.

The paradox of NDF is that while it can be a negative indicator of quality it is also required by ruminant animals.

Acid Detergent Fibre (ADF)

Acid detergent fibre is the portion of the forage that remains on the filter after a finely ground forage sample is treated with a detergent and strong acid. It includes the largely digestible cellulose, indigestible lignin and inorganic silica. Acid detergent fibre is important because it is negatively correlated with digestibility of forages. As the ADF increases, the forage becomes less digestible, primarily because the amount of indigestible lignin is increasing. Total digestible nutrients (TDN) values are calculated directly from ADF values as follows:

- Corn silage: TDN = 87.8 – (0.70 x ADF%)

- Legumes and grasses: TDN = 88.9 – (0.79 x ADF%)

Note that TDN declines less rapidly with increasing ADF in corn silage than in grass and legumes.

Lignin and silica

Lignin is the wood-like, non-carbohydrate component that cannot be digested by ruminants. Further, lignin decreases availability of cellulose and hemicellulose. The lignin fraction can be determined by further treatment of the ADF fraction with a very strong acid. All plants have the capacity to accumulate significant quantities of silica (or sand) although corn does not accumulate as much silica as many grasses. The silica fraction is left as ash after a forage sample is ignited in a special furnace. Mud or dust picked up on the corn will add to the silica content. Silica content can be reduced by raising the cutting bar (see Effect of Cutting Height).

J. Harrison and L. Van Wieringen

Washington State University, Puyallup, WA

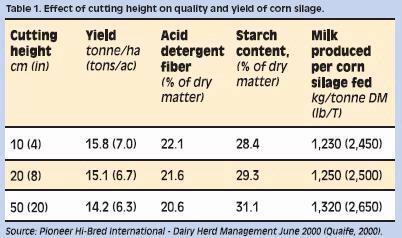

At a given maturity, the nutritive value of corn silage can be changed by altering the cutting height. This has been called hi-chop or super silage and is the result of leaving as much as 50cm (20inches) of the lower portion of the stover unharvested (Quaife, 2000). Raising the cutting bar lowers the fibre content and increases the starch content compared to conventional cutting height. While a more digestible forage is harvested, there is also a loss in yield of harvested forage (Table 1). The economics of this practice varies from farm to farm.

Table 1. Effect of cutting height on quality and yield of corn silage.

S.C. Fransen

Washington State University, Prosser, Washington

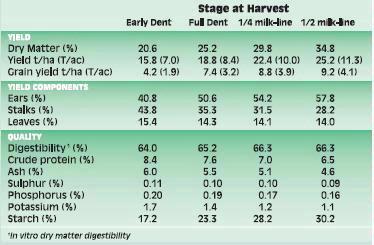

The yield of corn silage in our trials ranged from 15.8 t/ha (7.0 T/ac) with 20.7% dry matter content at the early dent stage to 25.2 t/ha (11.2 t/ac) with 34.8% dry matter at ½ milk-line stage (Table 1). If the crop were to remain in the field longer, harvestable yields would probably decline because of leaf senescence and drop, stalk breakage, lodging and pest damage. Silage corn yield is a sum of its 3 yield components: ears, stalks and leaves. Whole-plant dry matter content is highly related to corn ear maturity, since stalks and leaves retain high concentrations of plant moisture. With increasing crop maturity, the percentage of ears increase and stalks decrease, but the rate of this change declines from dent to 1/2 milk-line. Although stalk and leaf percentages decrease with advancing crop maturity, the ratio of leaves to stalks increases with maturity. Nevertheless, percentage of stalks remains proportionally higher than percentage of leaves. Leaf percentage remains similar after the crop reached the dent stage of growth. The average silage corn plant produces about 20 leaves, but they range from 12 to 25 leaves.

In our trials, digestibility of whole plant silage corn increased slightly after the crop reached the early dent stage (Table 1). Whole plant digestibility was generally related to the percentage of ears. Starch percentage followed the same pattern as total grain per acre. Crude protein percentage decreased as the crop matured, due to increasing ear percentage. Percent ash also decreased with advancing crop maturity. Three important minerals within the ash component are sulphur, phosphorus and potassium. Concentration of potassium declined more rapidly with maturity than sulphur or phosphorus.

Table 1. Change of yield, yield components and nutritional parameters with advancing maturity of irrigated corn in the Pacific Northwest (based on 64 hybrids, 4 years and 2 locations).

M.L. SWIFT

Abbotsford Veterinary Clinic, Abbotsford, British Columbia

Corn silage provides a palatable source of energy, protein and minerals for ruminant animals. However, like all forages, corn silage is inherently variable in nutrient value due to hybrid, climatic conditions, maturity upon harvest and conservation methods as shown in Table 1.

Table 1. Nutrient values for 83 samples of corn harvested at different maturities in the lower Fraser Valley region of British Columbia. (Range of values in brackets)

|

Maturity of Corn |

|||

| Immature | Intermediate | Mature | |

|

DRY MATTER (DM) (%) |

22.2 (18.0-24.2) | 27.5 (25.0-29.5) | 32.0 (30.0-38.7) |

|

FIBRE |

|||

| Acid Detergent Fibre (%DM) | 30.5 (26.1-38.2) | 28.4(24.0-33.7) | 25.7 (22.4-29.6) |

| Neutral Detergent Fibre(%DM) | 49.3 (44.7-58.3) | 45.6 (39.6-54.1) | 42.3 (37.7-48.2) |

| NDF Disappearance(%at 30h) | 54.8 (51.0-59.0) | 52.8 (44.0-59.0) | 51.7 (46.0-57.0) |

| Lignin (% of NDF) | 6.8 (4.1-8.2) | 7.1 (4.6-9.2) | 7.2 (6.1-8.6) |

|

SOLUBLE CARBOHYDRATES |

|||

| Starch (%DM) | 17.2 (0.5-26.4) | 26.0 (14.5-33.4) | 29.8 (20.9-37.6) |

| Sugar (%DM) | 3.5 (0.5-12.2) | 2.5 (0.4-10.7) | 1.8 (1.0-3.3) |

| nonstructural carbohydrates* | 34.3 (18.4-42.1) | 38.9 (26.0-45.4) | 42.8 (36.8-48.5) |

|

PROTEIN |

|||

| Crude Protein (CP) (%DM) | 9.5 (8.1-12.1 | 8.7 (6.6-11.7) | 8.4 (7.4-9.8) |

| Soluble Protein (% of CP) | 52.8 (34.3-69.1) | 56.2 (29.1-76.5) | 52.6 (30.7-73.5) |

| ADF-CP (% of CP) | 10.4 (7.7-13.8) | 10.1 (6.1-18.8) | 9.9 (6.7-14.6) |

| NDF-CP (% of CP) | 18.7 (9.1-36.2) | 15.3 (8.9-38.8) | 14.6 (8.0-28.7) |

|

FAT |

3.2 (2.1-5.3) | 3.4 (2.4-5.5) | 3.2 (2.6-4.0) |

|

MINERALS |

|||

| Calcium (%DM) | 0.23 (0.13-0.56) | 0.18 (0.09-0.35) | 0.18 (0.12-0.28) |

| Magnesium (%DM) | 0.16 (0.12-0.25) | 0.14 (0.07-0.23) | 0.15 (0.10-0.22) |

| Phosphorus (%DM) | 0.19 (0.13-0.27) | 0.2 (0.13-0.25) | 0.19 (0.14-0.26) |

| Potassium (%DM) | 1.10 (0.63-1.61) | 1.0 (0.68-1.34) | 0.88 (0.62-1.18) |

| Ash (%DM) | 5.5 (3.9-10.8) | 4.8 (3.1-8.9) | 4.5 (3.4-5.8) |

Energy

Corn silage is included in ruminant rations primarily as a source of energy. The starch in corn grain accounts for approximately 45% of the energy value of corn silage. Table 1 shows that immature corn silage (defined as DM less than 25%) contains approximately 10% units less starch than more mature corn silage (DM more than 25%). Microbial digestion of cellulose and hemicellulose (NDF fraction) in the rumen contributes a further 25% to the energy value of corn silage. The remaining 30% of energy in corn silage comes from sugars, pectin, organic acids, crude protein and crude fat. Traditionally the energy content of feedstuffs has been expressed in terms of TDN (total digestible nutrients) or NE (net energy of lactation or gain). Values for TDN and NE of corn silage and other forages are computed using regression equations based on acid detergent fibre (ADF) content (Table 2 ) which broadly represents the content of cellulose and lignin contained within the plant.

Table 2. Prediction equations for energy content of corn silage based on fibre analysis.

| Location | Equation |

| Midwest | %TDN = 87.84 – (0.70 x ADF) |

| New Hampshire | NE lactation = 0.996 – (0.0126 x ADF) |

| New York | NE lactation = 0.94 – (0.008 x ADF) |

| . | % TDN = 31.4 + (53.1 x NE lactation) |

Although this approach accounts for the increasing grain content (ADF decreases, energy increases) and increasing fibre content (ADF increases, energy decreases) as the corn plant matures, it does not account for variation in starch or fibre digestibility.

Over the past decade, there has been increasing interest in improving nutrient value of silage corn hybrids by increasing digestibility of its fibre, in particular, the NDF fraction. Recent studies confirm that digestibility of the NDF fraction affects dry matter intake and milk production (1). In these studies, a 1-unit improvement in NDF digestibility increased dry matter intake by 0.17 kg (0.37 lb) per day and production of milk (4% fat corrected) by 0.25 kg (0.55 lb) per day.

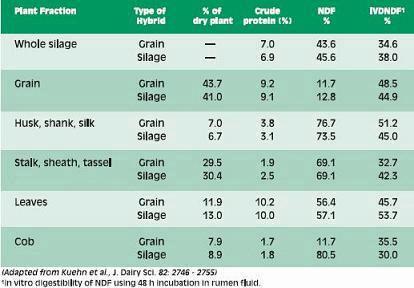

Table 3 provides an interesting comparison between two corn hybrids, one selected for grain the other for silage production. Digestibility of NDF in the stalks and leaves was approximately 10% greater in the silage hybrid than in the grain hybrid. Since these plant fractions represent over 40% of the plant structure, NDF digestibility was 3.4% greater for the silage than for the grain hybrid.

Table 3. Comparison of corn hybrids developed for grain and silage: plant components and their concentrations of crude protein, neutral detergent fibre (NDF) and digestibility of NDF (IVNDF).

Recent work showed a large range in the NDF digestibility of corn stover in hybrids tested at two sites in British Columbia (Table 4). Digestibility of NDF was tested as the proportion of the NDF that disappeared after 30 h of incubation in rumen fluid. The differences among hybrids shown in Table 4 are reflected in the data presented in Table 1 for immature (DM < 25%) and normal (DM >25%) corn silage samples. Silage harvested early showed an eight percentage point spread between lowest and highest NDF digestibility (51 to 59%). As the corn silage was allowed to mature, the differences between hybrids became increasingly evident as the variation in NDF digestibility increased to fifteen percentage points, ranging from 44 to 59%. Interestingly, there was no relationship between NDF digestibility and the content of DM or NDF in the sample.

Table 4. Values for NDF and NDF digestibility in stover from hybrids grown in coastal BC in 2001

| Location | Hybrids | NDF % | NDF digestibility (%) |

| SAANICH, BC | DK3947 | 59.4 | 48.0 |

| Funk 4066 | 59.7 | 51.0 | |

| Hyland 2240 | 62.6 | 43.7 | |

| Hyland S009 | 61.7 | 47.0 | |

| Hyland S012 | 61.7 | 52.7 | |

| NK 2555 | 62.5 | 48.0 | |

| Pioneer 39K40 | 61.7 | 46.7 | |

| Pioneer 39R42 | 61.8 | 47.7 | |

| Pioneer 39T68 | 65.3 | 47.7 | |

| TMF 2126 | 60.5 | 49.7 | |

| UAPDG 7485 | 59.6 | 48.3 | |

| Pioneer 38F70 | 63.8 | 47.7 | |

| AGASSIZ, BC | Pioneer 38F70 | 68.2 | 42.3 |

| Excel | 64.5 | 46.3 | |

| Garst 8707 | 65.2 | 43.7 | |

| Pride K378 | 68.6 | 44.0 | |

| N35R7 | 65.4 | 41.3 | |

| Pioneer 37Y15 | 64.0 | 43.0 | |

| Pioneer 3845 | 68.6 | 46.0 |

In light of the work showing the effect of NDF digestibility on dry matter intake and subsequent production, producers are urged to incorporate nutritional quality assessments into their decision-making processes in choosing hybrids for corn silage production. Recently, computer software has been introduced which balances rations for ruminants based on digestibility and dry matter intake. One example is the program associated with the Nutrient Requirements of Dairy Cattle (2) in which the TDN or energy value of corn silage is computed as the sum of digestible nonfibre carbohydrates (e.g. starch), digestible crude protein, digestible fatty acids and digestible NDF.

Minerals: The calcium to phosphorus ratio in corn silage is approximately 1:1 as shown in Table 1. However there is a large range in mineral content of corn silage. The low potassium content (<2%) makes corn silage ideal for incorporation into diets for dry cows less than 21 days (close-up) from parturition.

J. BAAH¹ , J.A. SHELFORD¹ and M.L. SWIFT²

¹ Faculty of Agricultural Sciences, University of British Columbia, Vancouver, British Columbia and ² Abbotsford Veterinary Clinic, Abbotsford, British Columbia

Sources of protein: microbial and rumen-bypass

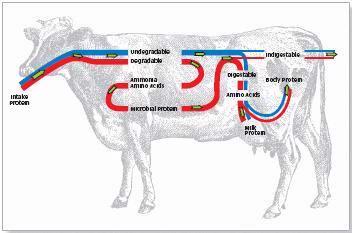

All animals need to consume protein to supply the building blocks, called amino acids, that are used to build the proteins in muscle, membranes, enzymes and milk. Ruminant animals are different from non-ruminants in how they obtain amino acids. Non-ruminant animals derive all their amino acids directly from the protein in their feed. Ruminants derive amino acids from two sources: from the microbes that grow in the rumen and are then digested in the intestines, and from the feed protein that passes through the rumen and is then digested in the intestines (Fig. 1). This protein is commonly referred to as bypass protein.

Figure 1. Schematic representation of protein digestion and utilization in the cow.

Microbes in the rumen require protein (nitrogen) and energy to grow and multiply. In order to acquire nitrogen for growth, these microbes break down feed protein into both amino acids and non-protein nitrogen compounds such as ammonia. Microbes derive energy from the carbohydrates (sugars, starches, cellulose and hemicellulose) found in grains and forages. Microbes pass out of the rumen and are digested in the small intestine providing 40 to 80% of the ruminant’s requirement for metabolizable protein, depending on stage of growth or lactation.

Rumen microbes grow best when the supply of energy and nitrogen is in synchrony. Slowly digesting carbohydrates such as cellulose are most compatible with protein sources having slow rates of degradation (breakdown) that provide a steady supply of nitrogen. Frequent meals also help to provide a steady supply of nitrogen for the microbes.

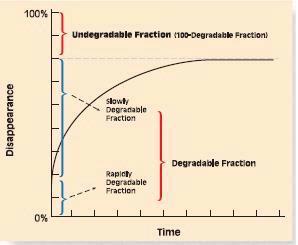

The proteins in corn silage and other forages contain both degradable and undegradable fractions (Fig. 2). The overall degradability of protein in the rumen is determined by two factors: the portion of protein that is digested by microbes in the rumen and the speed of digestion in the rumen relative to rate of passage out of the rumen. If the rate of passage out of the rumen is high (high feed intake), then the microbes will not have a chance to degrade the feed protein. Hence, rumen protein degradability will be decreased. The degradable protein fraction can be subdivided into those proteins that degrade rapidly and those that degrade over a longer period of time.

Figure 2. Disappearance of protein fractions in forages as a function of time.

Protein in silage corn

Although corn silage is low in crude protein (CP) content, a ration where corn silage is the main source of forage can contribute up to 25% of the crude protein requirement of a high producing dairy cow. Of interest is the proportion of corn silage crude protein that is soluble (assumed to be readily degradable) in the rumen and that which is slowly degradable (bypass protein) as shown in Table 1.

Microbes can use soluble protein if sufficient carbohydrate is supplied in the diet. Excess soluble protein will be absorbed through the rumen wall and excreted through milk (Milk Urea Nitrogen) or urine. As shown in Table 1, there is a large range in soluble crude protein values in corn silage. Soluble crude protein is increased by the ensiling process, hence samples of “green” or uncured silage will contain less crude protein in the soluble form. Similarly, there is a large variation in the amount of crude protein in corn silage.

Table 1. Crude protein degradation characteristics of corn silage collected from farms in coastal British Columbia

|

Mean |

Miniumum |

Maximum |

|

|

Soluble CP (% of CP) |

47.4 |

12.7 |

80.1 |

|

Bypass CP (% of CP) |

43.5 |

16.2 |

71.0 |

|

Rate of Ruminal CP Degradation (% per h) |

4.4 |

0.1 |

11.1 |

From ML Swift, 2003. PhD Thesis, U British Columbia, Vancouver, BC.

References

1. Swift, M.L. 2003. Ph.D. Thesis. University of British Columbia.

P.S. MIR

Agriculture and Agri-Food Canada, Lethbridge, Alberta

The two grain crops grown extensively for whole-plant silage in North America are corn and barley. At the appropriate maturity the yield and energy content of these crops is very high and both crops are relatively easy to ensile and to use as feed for dairy and beef cattle. Other than the slightly higher protein content of barley silage relative to corn silage (11 versus 8%), there are generally only small differences in composition between the two silages. The content of fat and starch varies with maturity and grain content. Although most of the energy acquired by the ruminant is from the starch and fibre fractions of silage, the fat content also has significant impact. Corn silage with 50% grain has from 2 to 7% fat depending upon the variety and maturity at harvest, while barley silage has less than 2% fat. The fatty acid composition of the two silages is similar. Among nutrients, fat yields the most calories per unit weight. Although the fat concentrations are small, the total amount consumed by an animal can be substantial. Dairy animals that consume up to 50% of diet dry matter as silage or beef cows that consume only silage through the winter months would receive about 0.44 kg (1 lb) of fat per day from corn silage and 0.24 kg (0.5 lb) from barley silage.

Figure 1. Intercropping corn with oilseed sunflower produces a high oil silage (Agassiz, British Columbia).

Unlike carbohydrates, fat does not undergo fermentation losses in the rumen. Instead, fat is hydrolysed in the rumen into its components, glycerol and fatty acids. The glycerol is fermented in the same manner as carbohydrates. Both barley and corn silages contain about 70% unsaturated fatty acids. The saturated fatty acids are incorporated unchanged into bacterial biomass while most unsaturated fatty acids are hydrogenated before absorption by the bacteria. Some fatty acids are also absorbed directly across the rumen wall, whereas the fatty acids associated with the bacteria pass to the small intestine. Here the fats are released from the microbes and absorbed via micells, formed through the action of bile from the gall bladder and lipases from the pancreas. Interestingly, the that will escape degradation (bypass protein) by rumen microflora. A recent study (1) showed that on average, 28% of corn silage crude protein escaping degradation in the rumen will be digested in the small intestine. However, values ranged from 0 to 58%. Hence, total tract disappearance of corn silage crude protein ranged from 50 to 100% with a mean value of 80%. Further study is needed to determine the reasons for the wide ranges in soluble and slowly degradable protein fractions in corn silage. released fatty acids decrease viscosity of intestinal contents (1), thereby improving efficiency of digestion and absorption. However, ruminants cannot withstand high levels of dietary fat as it interferes with rumen function; maximum added dietary fat of 6% on dry matter basis has been suggested (2).

Dietary fat in the rumen can influence the fermentation products formed. Long-chain unsaturated fatty acids are toxic to certain protozoa that colonize the rumen. Providing 6% oil in the diets of sheep, as either sunflower oil or whole sunflower seeds, substantially reduced protozoa in the rumen for over 84 d (3). Protozoa are closely associated with methaneproducing bacteria so decreases in protozoa numbers reduces these bacteria and reduce methane production. In a trial conducted in Alberta, feeding sunflower oil at 6% of diet reduced methane emission in cattle by 21.5% (4). Generally, protozoa are predatory on bacteria in the rumen so it can be expected that reductions of ruminal protozoa from feeding fat would lead to an increase in bacterial biomass. Thus dietary protein supplementation can be reduced, possibly minimizing excre- tion of N in manure. Although detailed studies have not been conducted, it can be expected that dietary oil from corn or barley silage may help to reduce the requirement for rumen bypass protein. This may help to explain the benefit of corn silage in managing nitrogen on dairy farms.

Both corn or barley fat contain high proportions of the three unsaturated fatty acids, oleic (C18:1), linoleic acid (C18:2) and linolenic acid (C18:3). These unsaturated fatty acids can serve as hydrogen sinks at the double bonds in their structure which directly decrease methane production. In fact, a large proportion of unsaturated fatty acids in the feed are bio-hydrogenated in the rumen. The process of bio- hydrogenation has several steps and various partially hydrogenated or isomerised compounds leave the rumen prior to completion of hydrogenation. Many of these compounds have been found to have biological activity. The cholesterol-lowering omega-3 fatty acids, derived from linolenic acid rich diets, will transfer into both milk and meat to provide the consumer with healthful foods.

There is now interest in an anticarcinogenic compound derived from omega-6, linoleic acid, called conjugated linoleic acid (CLA). It occurs naturally in ruminant products such as milk and meat, and additions of oil or oil-seed to ruminant diets can increase its concentration. It was originally believed to be produced exclusively in the rumen, but there is evidence that this fatty acid is produced at least at two locations in dairy cattle and secreted into milk. In the rumen during biohydrogenation the linoleic acid is converted to CLA or to an alternate oleic acid, which passes from the rumen into the intestines. The oleic acid is absorbed from the intestines, enters circulation in the animal, then is taken up by the mammary tissue where it is converted to the CLA by enzymes. Provision of unprotected dietary oil to dairy cows at 4% of diet will increase the CLA content of milk (4 mg/g fat) three- to fourfold. Feeding entire oil-seeds is more effective than just the extracted oil (5).

In view of the importance of dietary oil for ruminants, there may be advantage in re-examining the production and feeding of silages from inter-crops of corn and high-oil crops such as sunflowers (6, 7) on diet compositional and production parameters as well as the production of bio-active compounds and perhaps specialty milk or meat products.

References

Fisher, L.J., S. Bittman, Z. Mir, P.S. Mir and J.A. Shelford 1993. Nutritional evaluation of ensilges made from intercropped corn and sunflowers. Can. J. Anim. Sci. 73, 539-545.

He, M.L., P.S. Mir, K.A. Beuachemin, M. Ivan and Z. Mir 2003. Effects of dietary sunflower seeds on lactqation performance and conjugated linoleic acid (CLA) content of milk. IX World Congress of Animal Production, Porto Alegre, Brazil Oct 25 -3,12003. Page 13.

Ivan, M., P.S. Mir, K.M. Koenig, L.M. Rode, L. Neil, T. Entz and Z. Mir 2001. Effects of dietary sunflower seed oil on rumen protozoa population and tissue concentration of conjugated linoleic acid in sheep. Can. J. Anim. Sci. 41, 215- 227.

McGinn, S.M., K.A. Beauchemin and D. Columbatto 2003. Use of novel ingredients to reduce methane emissions from beef cattle. IX World Congress of Animal Production, Porto Alegre, Brazil Oct 25 -3,12003. Page 40.

Mir, P.S., M. Ivan, G.J. Mears, B.F. Benkel, C.M. Ross, S.D. Husar and Z. Mir 2002. Effect of sunflower oil on sheep intestinal digesta viscosity, composition and amylase activity. Small Ruminant Res. 45, 33-38.

Mir, Z. 1988. A comparison of canola acidulated fatty acids and tallow as supplements to ground alfalfa diet for sheep. Can J. Anim. Sci. 68, 762-767.

Mir, Z., P.S. Mir, S. Bittman and L.J. Fisher 1992. Ruminal degradation characteristics of corn and corn-sunflower intercropped silages prepared at two stages of maturity. Can. J. Anim. Sci. 72, 881-889.

M.L. SWIFT

Abbotsford Veterinary Clinic, Abbotsford, British Columbia

As corn silage provides a palatable and digestible source of energy, it is not uncommon that corn silage will comprise a substantial amount of the forage component of the diet formulated for lactating dairy animals. In balancing these types of rations, the following points should be noted:

- Reconsideration of bypass protein sources used to balance lysine requirements.

Corn, whether in the form of grain, by-products such as distillers grains or as silage, is limiting in the amino acid lysine. Lysine is recognized as one of the most frequently limiting essential amino acids in metabolizable protein used by cattle to produce meat or milk protein. Feeding corn based by-products such as corn gluten meal, or corn distillers grains accentuates low lysine levels in high corn silage diets. Therefore, bypass protein sources such as soybeans, soybean meal, fish meal or blood meal are recommended for inclusion in rations comprised of corn silage as the primary forage source. - Control of starch levels to maintain rumen pH and fibre digestion.

Corn silage consists of stover (leaves, stalks, husks) and the ear (cob and grain). The ear is comprised of the cob (16%) and corn grain (84%). Therefore, corn silage contains varying amounts of readily-available energy in the form of corn grain or starch.Typically, it is recommended that diets for lactating dairy cattle contain 25 to 30% starch on a dry matter basis. However, there can be a great deal of variation noted in the starch content of different samples of corn silage. For example, results from the Pacific Field Corn Association’s evaluation trials for 2003 (www.farmwest.com) show a range in grain content of between 30.6 and 52.5% for early hybrids.This is equivalent to a range in starch content of 19.7 to 32.2% (assuming the ear contains 64% starch). Analyses of corn silage samples harvested and processed late in 2003 indicate starch levels reaching as high as 40%. The failure to account for this additional starch provided by the corn silage can lead to ruminal acidosis and laminitis. Laboratory tests are available to determine the starch content. Another rough method is to calculate the Non-Fiber Carbohydrate (NFC) as: 100 – (CP + Ash + Fat + NDF). - Recognition of the importance of effective fibre in high corn silage diets.

Originally, effective fibre was defined as the minimum amount of fibre needed to maintain milk fat percentage (through optimal fibre digestion and pH in the rumen). Several systems have been proposed to measure effective neutral detergent fibre (NDF). These systems have suggested that NDF in corn silage is approximately 90% as effective as NDF in grass silage or long grass hay. As fibre is needed to stimulate chewing activity and saliva production, and to maintain rumen pH, it is important to monitor the effective NDF content of high corn silage diets. - If feeding fat in the diet, reallocation of sources to rumen inert forms.

Corn silage contains approximately 3% crude fat, in the form of corn oil from the kernel. Feeding substantial amounts of high-grain corn silage can contribute approximately 225 grams of unsaturated fat to the ruminal environment. Therefore, if increasing the amount of fat in the ration is being considered, this fat should be added in the form of ruminally inert (bypass) fats (see Fat in Corn Silage section). - Rebalancing of mineral packages to reflect increased need for calcium and magnesium.

Corn silage contains low concentrations of calcium and magnesium as compared to other forage sources such as grass silages or hays. Therefore, it is important to further supplement these important macro-minerals when the diet contains a high level of corn silage. Corn silage contains substantially less potassium making it a popular choice for inclusion in transition cow diets. However, it is important to ensure adequate potassium levels during periods of heat stress.

J. HARRISON and L. VAN WIERINGEN

Department of Animal Sciences, Washington State University, Puyallup, Washington

Introduction

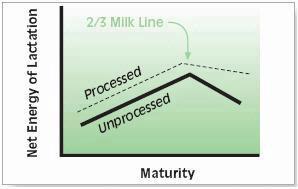

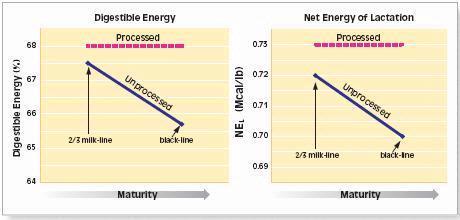

The major factor affecting the quality of corn silage is stage of maturity at harvest. Fig. 1 depicts the change in energy value of silage corn as it progresses in maturity. The initial increase in energy content is attributed to accumulation of highly digestible starch in the ear and the high fibre digestibility of the stover fraction of the corn plant. The point of inflection occurs at about 2/3 milk-line stage of the corn kernel (see Corn Growth and Development section). Beyond this point the increased nutritive value in the corn kernel is offset by a decrease in stover digestibility and passage of undigested corn kernels into feces (1). For mechanically processed corn silage, digestibility tends to plateau past 2/3 milk-line due to counteracting effects of increased starch digestibility and decreased stover digestibility.

Figure 1. Relationship between maturity and energy content in silage corn with and without processing.

How Processing Affects Quality of Corn Silage

Digestion in the Rumen

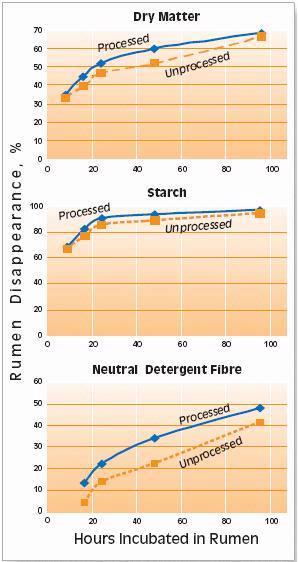

Our studies have shown that processing corn silage consistently increased total disappearance in the rumen of both starch and fibre (NDF) fractions (Fig. 2). Therefore, processing also tended to improve the rate of whole crop dry matter disappearance in the rumen especially in warm, dry seasons when the silage was relatively dry for its stage of maturity at harvest.

Figure 2. Processing affects rate of dry matter (top) starch (middle) and neutral detergent fibre disappearance in the rumen.

For both processed and unprocessed corn silages, the amount of disappearance of starch in the rumen was high (> 93%) after 96 hours of incubation (Fig. 2-middle). Despite variability, there was a trend for processed corn silage to have approximately a 3.0 percentage unit improvement in ruminal starch digestibility. Processing particularly improved rate of starch disappearance in drier silages (Fig. 2-middle). Similarly, processing improved rate of fibre (NDF) disappearance most in silage grown under relatively warm and dry conditions (Fig. 2-bottom).

Total-Tract Digestion

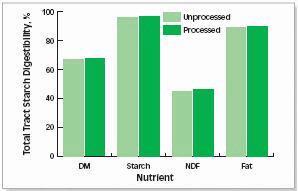

The increase in total tract starch digestibility due to mechanical processing was similar to the increase in ruminal starch digestibility. In 11 trials, we found that processing improved total tract digestibility of corn silage by almost 1% unit. This overall increase in digestibility can be attributed to improvements in total tract digestibility of starch (0.84% units), NDF (1.65% units), and fat (0.75% units) (Fig. 3).

Figure 3. Total tract digestibility of dry matter (DM), starch, NDF and fat.

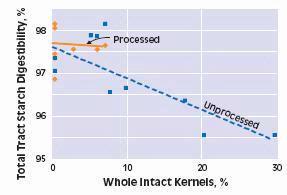

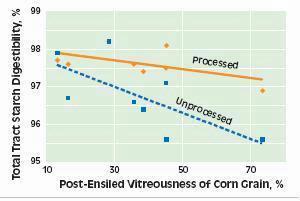

The improvement in NDF digestibility was consistently greatest (4 to 10%) for mature corn silage. This trend was also observed for starch digestibility (1 to 1.3%). The effect of processing on starch digestibility of relatively immature corn (two-thirds milkline) was more variable (0.7 to 2.5%). In unprocessed corn, total tract starch digestibility decreased as the amount of whole intact kernels increased, whereas in processed corn, the amount of intact kernels was minimal so total-tract starch digestibility was always high (Fig. 4-left).

Figure 4. Effect of percent whole intact kernels (top) and post-ensiling vitreousness (bottom) on whole tract starch digestibility.

The amount of vitreous and floury starch in the kernels in corn silage plays a significant role in total tract starch digestibility (Fig. 4-top). Vitreous starch tends to be harder for cows to digest because the starch granules are embedded in a dense protein matrix. In unprocessed corn silage, as the amount of vitreous starch increases, total tract starch digestibility decreases (Fig. 4). Processing disrupts the dense protein matrix of vitreous starch making it available for digestion. Therefore, total-tract starch digestibility is less influenced by amount of vitreous starch in processed than in unprocessed corn silage.

Energy Content of Total Mixed Rations Containing Processed Corn Silage

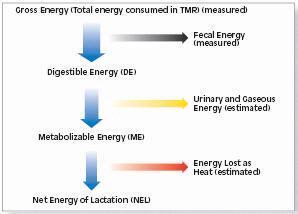

We tested the energy contents of the total mixed rations (TMR) containing 27% corn silage (harvested at . milk-line to black-line) which was either unprocessed or processed. These feeding studies involved measurements of all inputs and outputs (Fig. 5). Note that digestible energy (DE) provides the most accurate energy values because it is based on direct measurements of energy consumed (gross energy) minus energy excreted as feces. In contrast, metabolizable energy (ME) and net energy of lactation (NEL) are based on estimates of energy loss in urine, expelled methane and body heat. However the NEL values are particularly useful for ration balancing.

Figure 5. Energy partitioning system

The trials showed that processing of the corn silage improved energy content of the whole mixed ration. The difference in energy content was greater at black-line than at twothirds milk-line stage (Fig. 6). Digestible energy for diets with processed corn silage was about 0.7% greater at two-thirds milk-line and 3.5% greater at black-line than for diets with unprocessed corn silage. The concentration of net energy of lactation (NEL) of processed corn silage diets was about 0.6% greater at two-thirds milk-line and 3.9% greater at black-line than NEL of unprocessed corn silage diets.

Figure 6. Effect of processing corn silage at two stages of maturity on digestible energy (left) and net energy of lactation, NEL (right) of the total mixed ration containing 27% corn silage (for MJ/kg, multiply Mcal/lb X 0.53).

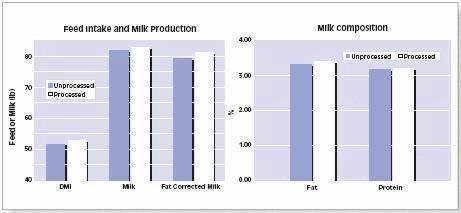

Processing Corn Silage Improves Milk Production

Johnson and Harrison (1) showed that, over 22 trials, cows fed diets based on processed corn silage produced an average of 0.5 kg (range of -0.5 to 1.7 kg) or 1.1 lb (range of -1.1 to 3.7) more milk per day than cows fed diets with unprocessed corn silage (Fig. 8). In addition, processing increased milk fat concentration by 0.08% (-0.18 to 0.29). Hence fat corrected (3.5%) milk production for cows fed processed corn silage based diets was 0.9 kg (0.8 to 2.2) or 2.0 lb (- 1.78 to 4.84) greater than for cows fed diets with unprocessed corn silage. Milk protein concentration was relatively unaffected by processing. Some of the improved milk production can be attributed to increased feed intake, generally 0.5 (-1.5 to 1.4) kg per cow per day or 1.1lb per cow per day (-3.3 to 3.1). Where milk production was not increased by processing, this was due to either decreased feed intake (for unknown reasons) or to inadequate fibre in the diet caused by reduction in particle size (see below).

Figure 8. Effect of feeding unprocessed and processed corn silage on feed intake (DMI) and milk production (left) and milk composition (right) (1 lb = 0.45 kg).

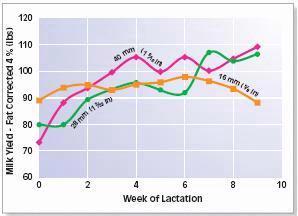

Silage Processing Affects Optimum Chop Length

Processed corn silage should be chopped at a longer theoretical length of cut (TLC) than unprocessed silage to maintain adequate effective fibre in the diet. It is now common to recommend that processed corn silage be cut at 19 to 25 mm (¾ to 1 in) TLC. Table 1 compares performance of cows fed conventional unprocessed corn silage at 10 mm (3/8 in) chop to processed corn silage chopped at 10 mm (3/8 in), 14 mm (9/16 in), and 19 mm (¾ in). For processed corn silage, the longer cuts resulted in less sorting of the diet and provided for the best overall performance (at least equal milk, increased protein and fat, and lower requirement for power).

We recently found that the optimum length of chop for processed corn silage depends on stage of lactation (6). Figure 9 shows that in the first four weeks of lactation, cows performed best on processed corn silage with a relatively short chop (16 mm or 5/8 in), whereas from 4 to 9 weeks, cows performed consistently better on much longer (40 mm or 1 9/16 in) chop lengths.

Figure 9. Effect of chop length of processed corn silage on fat-corrected (4%) milk production through first 10 weeks of lactation.

Table 1. Effect of chop length and processing on feed intake and production of milk and milk components in kg (lb).

|

Chop Length |

Unprocessed |

Processed |

||

|

|

10 mm (3/8in) |

10mm (3/8in) |

14mm (9/16in) |

20mm (3/4in) |

|

Particle length mm (in) |

9.4 (3/8) |

6.7 (1/4) |

8.9 (1/3) |

9.2 (1/3) |

|

Feed intake kg (lb) |

25.2 (55.4) |

25.9 (56.9) |

25.9 (56.9) |

25.8 (56.7) |

|

Milk production kg (lb) |

44.8 (98.6) |

46.5 (102.2) |

45.3 (99.7) |

46.1 (101.4) |

|

Fat yield kg (lb) |

1.3 (3.0) |

1.4 (3.2) |

1.4 (3.1) |

1.4 (3.1) |

|

Protein yield kg (lb) |

1.4 (3.1) |

1.5 (3.2) |

1.5 (3.2) |

1.5 (3.2) |

Does it Pay to Process Corn Silage?

Our economic analysis of processing takes into account many factors such as:

1) Increased costs

- Increased machinery cost (Shinners, 1999)

- Higher feed intake

2) Decreased cost

- Lower storage loss

3) Increased returns

- More milk

- Better milk composition (milk fat)

4) Other factors

- Milk production level

- % Corn silage in diet

- Effective fibre in diet

- Starch digestibility of diet

- Fibre digestibility of diet

- Specific energy requirements of harvester

- Throughput capacity of harvester

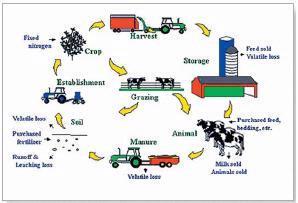

Our analysis was conducted using a computer model called DAFOSYM (8) which simulates the economic and environmental aspects of crop production, feed use, and nutrient cycling on a dairy farm (Fig. 10). For example, DAFOSYM can predict how increasing the amount of corn silage in the diet would affect milk production, ration costs, and overall economics at the whole farm level.

Figure 10. DAFOSYM simulates material and nutrient flows for various dairy farm systems over many years of weather and determines the economics of the farm.<

We tested the economic impact of processing on dairy farms having 100 or 400 high-producing Holstein cows that were fed processed corn silage at 40 and 75% of forage requirement, respectively (Table 2). On the 100-cow farm feeding 40% corn silage, processing improved packing in the silo and increased the digestibility of silage, which reduced requirement for supplemental grain and improved milk production by 2.6%. However, the amount of purchased feed increased because the cows fed processed corn silage were producing more milk and therefore consuming more feed. As in the previous analysis, increases in milk sales exceeded increases in production costs by almost 50/cow/year (Table 2). On the 400 cow farm, feeding processed corn silage for 75% of the total forage requirement, processing increased milk production by about 4% and the economic benefit was $95/cow/year.

Table 2. Economic Analysis of supplementing processed corn silage in the diet at 40 and 75% of the forage requirement (using DAFOSYM).

|

|

100 Cow Dairy |

400 Cow Dairy |

||

|

|

40% of forage requirement |

75% of forage requirement |

||

|

|

UNPROCESSED |

PROCESSED |

UNPROCESSED |

PROCESSED |

|

Corn silage produced, tonne (ton) DM |

245 (269) |

248 (273) |

1810 (1988) |

1820 (2002) |

|

*Purchased feed, tonne (ton) |

217 (239) |

220 (242) |

429 (472) |

449 (494) |

|

Milk production, kg/cow/year (lb/cow/year) |

10,410(22,900) |

10,680 (23,500) |

10,320 (22,700) |

10,770 (23,700) |

|

*Purchased feed & bedding, $ |

50,042 |

50,677 |

178,054 |

184,044 |

|

Net return to management, $/year |

44,820 |

49,605 |

287,265 |

325,163 |

|

Increase in income due to processing, $/cow/year |

– |

47.85 |

– |

94.75 |

* The amount of purchased feed increased because the cows fed processed corn silage were producing more milk and therefore consumed more DM.

Summary

It is commonly agreed that the desirable range of maturity to harvest corn silage is 1/2 to 2/3 milk line or 25-40% DM. If corn silage is mechanically processed before ensiling, as much as 10% additional energy can be gained from the silage. Chop lengths from 5 to 25 mm (¼ to 1 in) can be stored and fed effectively, with longer chop lengths suggested for processed silage. The length of chop should be based on whether or not the silage is mechanically processed and on other forages in the diet.

Recommendations for Feeding Processed Corn Silage

Since mechanically processed corn silage has reduced particle size and increased starch digestibility, several practical feeding recommendations are warranted:

1) The greater the amount of processed corn silage in the diet the greater the expected improvement in energy content of the diet.

2) Ensure that there is adequate effective fibre in the diet to avoid milk fat depression.

3) Increase the amount of corn silage in the ration progressively over several days to avoid rumen upset and possible acidosis (see Feeding High Corn Silage Diets section).

Effect of Processing Brown Midrib (bm3) Corn Silage

Does processing increase the silage quality from the highly digestible brown midrib (bm3) corn?

One study, using low ADF diets (15.5-16.5%), found that processing bm3 corn silage with 19-mm (¾ in) chop length did not significantly improve milk production (2, 3). The explanation was that processing increased (whole-tract) starch digestibility but decreased fibre digestibility and processing also reduced eating time. The conclusion was that processing did not affect milk yield because there was very little difference in particle size of material entering the rumen after the initial mastication. A recent study reported that milk production (3.5% fat-corrected) was greater for cows eating processed than unprocessed bm3 corn silage (43.3 vs. 39.3 kg or 95.3 vs. 86.5 lb). The benefit was due to greater in-situ DM disappearance and total tract nutrient digestibility rather than increased intake (4, 5).

References

1. Johnson, L. and J.H. Harrison 2001a. Effects of mechanical processing on the nutritive value of corn silage and performance characteristics in lactating dairy cows: 1 Introduction. Washington State University Dairy News. V 10, No 2, March 2001.

2. Schwab, E.C. and R.D. Shaver 2001. Crop processing and chop length effects in brown midrib on dry matter intake and lactation performance by dairy cows. J. Dairy Sci. 84, 197 (Suppl 1).

3. Schwab, E.C. and R.D. Shaver 2001a. Crop processing and chop length effects in brown midrib on chewing activity and mean particle size of silage and masticates. J. Dairy Sci. 84, 197 (Suppl 1).

4. Ebling, L., J.M. Neylon, D.H. Kleinschmit, J.M. Ladd, C.C. Taylor, and L. Kung, Jr. 2002a. Comparison of physical and chemical characteristics of mechanically processed brown midrib, unprocessed brown midrib, or processed normal corn silage. J. Dairy Sci. 85, 383 (Suppl 1).

5. Ebling, L., J.M. Neylon, D.H. Kleinschmit, J.M. Ladd, C.C. Taylor, and L. Kung, Jr. 2002b. Effect of feeding mechanically processed brown midrib (PBMR), unprocessed brown midrib (UBMR), or processed normal corn silage (P7511) in diets for dairy cows on DM intake, milk production and digestion. J. Dairy Sci. 85, 383 (Suppl 1).

6. Johnson, L. and J.H. Harrison 2001b. Kernel processing: Fermentation changes in the silo due to maturity and mechanical processing of corn silage. Washington State University Dairy News. V 10, No 4, May 2001.

7. Bal, M. A., R.D. Shaver, A.G. Jirivec, K.J. Shinners and J.G. Coors 2000. Crop processing and chop length of corn silage: Effects on intake, digestion, and milk production by dairy cows. J. Dairy Sci. 83, 1264-1273.

8. Rotz, C.A., L.M. Johnson, and J.H. Harrison 1999. Economics of corn silage processing on North America dairy farms. Applied Engineering in Agriculture. Vol 15(5), 411-421.

Additional References

Bolsen, K. 1995. Losses from the top spoilage in horizontal silos. Proc. 2nd National alternative feeds symposium. St Louis, MO. Sept. 245-26. Pp.159- 176.

Bolsen, K.K., J.T. Dickerson, B.E. Brent, R.N. Sonon, Jr., B.S. Dalke, C. Lin, and J.E. Boyer, Jr. 1993. Rate and extent of top spoilage losses in horizontal silos. J. Dairy Sci. 76, 2940-2962.

Fox, D.G., C.J. Sniffen, J.D. O’Connor, J.B. Russell, and P.J. Van Soest 1990. The Cornell Net Carbohydrate and Protein System for evaluating cattle diets. Part 1: A model for predicting cattle requirements and feedstuff utilization. Pages 7-83 in Search: Agriculture No. 34. Cornell Univ. Agric. Exp. Stn., Ithaca, NY.

Harrison, J., D. Davidson, and D. Linder 2001a. Evaluation of the nutritive value of low moisture corn silage stored in Ag Bag vs bunker silo. J. Dairy Sci. 84, 154 (Suppl 1).

Harrison, J.H., D. Davidson, and L. Johnson 2001b. Evaluation of processed corn silage harvested at three chop lengths. J. Dairy Sci. 84, 154(Suppl 1).

Harrison, J.H., and L. Johnson 2001. Management practices that enhance the nutritive value of ensiled forages. Proc. 10th International Symposium on Forage Conservation, Brno, Czech Republic.

Harrison, J.H., and L. Johnson 2001. Processed corn silage — what have we learned? Proc. Cornell Nutrition Conf.

Harrison, J. 2001. Corn silage management in bag and bunker silos. Proc. Pacific Northwest Animal Nutrition Conference.

Holmes, B.J. 1998. Choosing forage storage facilities. Proceedings of Dairy Feeding Systems, Management, Components and Nutrients Conference. NRAES-116. Ithaca, NY.

Jirovec, A.J., K.J. Shinners, R.D. Shavers, and M.A. Bal 1999. Processing wholeplant corn silage with crop processing rolls. Presented at the Feb 8-10, 1999 ASAE Ag Equip Tech Conf. Paper # 99AEC-105. Niles Road, St Joseph, MI 49085-9659 USA.

Johnson, L., J.H. Harrison, C. Hunt, K. Shinners, C.G. Doggett, and D. Sapienza 1999. Nutritive value of corn silage as affected by maturity and mechanical processing: A contemporary review. J. Dairy Sci. 82, 2813-2825.

Johnson, L. and J.H. Harrison 2001c. Effects of mechanical processing on particle size, pack density, and aerobic stability of corn silage. Washington State University Dairy News. V 10, No 3, April 2001.

Johnson, L. and J.H. Harrison 2001d. Kernel processing article # 4: Measuring rumen digestibility of processed corn silage using the macro in situ technique. Washington State University Dairy News. V 10, No 5, July/August 2001.

Johnson, L. and J.H. Harrison 2001e. Effects of Mechanical processing on ruminal and total tract digestibility in lactating dairy cows. Washington State University Dairy News. V 10, No 6, September 2001.

Johnson, L. and J.H. Harrison 2001f. Effects of Mechanical processing of corn silage on energy content of TMR fed to lactating dairy cows. Washington State University Dairy News. V 10, No 7, November 2001.

Johnson, L. and J.H. Harrison 2002. Economics of mechanical processing corn silage. Washington State University Dairy News. V 11, No1, February 2002.

Johnson, L., J.H. Harrison, D. Davidson, W.C. Mahanna, K. Shinners and D. Linder 2002. Corn silage management: Effects of maturity, inoculation, and mechanical processing on pack density and aerobic stability. J. Dairy Sci. 85, 434-444.

Johnson, L., J.H. Harrison, D. Davidson, J.L. Robutti, M. Swift, W.C. Mahanna and K. Shinners 2002. Corn silage management I: Effects of hybrid, maturity, and mechanical processing on chemical and physical characteristics. J. Dairy Sci. 85, 833-853.

Johnson, L., J.H. Harrison, D. Davidson, M. Swift, W.C. Mahanna and K. Shinners 2002. Corn silage management II: Effects of hybrid, maturity, and mechanical processing on digestion and energy content. J. Dairy Sci. 85, 2913-2927.

Johnson, L., J.H. Harrison, D. Davidson, M. Swift, W.C. Mahanna and K. Shinners 2002. Corn silage management III: Effects of hybrid, maturity, and mechanical processing on nitrogen metabolism and ruminal fermentation. J. Dairy Sci. 85, 2928-2947.

Johnson, L., J.H. Harrison, D. Davidson, W.C. Mahanna and K. Shinners 2002. Corn silage management III: Effects of hybrid, maturity, inoculation, and mechanical processing on fermentation characteristics. J. Dairy Sci. 85, in press.

Johnson, L., J.H. Harrison, D. Davidson, W.C. Mahanna and K. Shinners. 2002. Corn silage management III: Effects of hybrid, chop length, and mechanical processing on digestion and energy content. J. Dairy Sci. 85, in press.

Johnson, L., J.H. Harrison, D. Davidson, C. Hunt, W.C. Mahanna and K. Shinners 2002. Corn Silage Management: Effects of Hybrid, Maturity, Chop Length, and Mechanical Processing on Rate and Extent of Digestion. J. Dairy Sci. 85, in press.

Quaife, T. 2000. Try cutting corn silage at 20 inches. Dairy Herd Management. June 2000. Pp. 62-64.

Rotz, C.A. and R.E. Muck 1994. Changes in forage quality during harvest and storage. In Forage Quality and Evaluation. Amer. Soc. Agron., Crop Sci. Soc. of America, and Soil Sci. Soc. of Amer. Ed: Fahey.

Rotz, C.A., D.R. Buckmaster, D.R. Mertens, and J.R. Black 1989. DAFOSYM: A dairy forage system model for evaluating technologies and management strategies in forage conservation. J. Dairy Sci. 72, 3050-3063.

Ruppel, K.A., R.E. Pitt, L.E. Chase and D.M. Galton 1995. Bunker silo management and its relationship to forage preservation on dairy farms. J. Dairy Sci. 78, 141-153.

Shinners, K.J. 1999. Forage harvester crop processors and other new hay and forage equipment. In Proc. Tri-state Dairy Nutrition Conference, 137-166. 20-21 April, Fort Wayne, Ind. Columbus, Ohio; The Ohio State University.

Wallentine, M.V. 1993. Silage storage systems in the arid west. In Proceedings of Silage Production: From Seed to Animal. NRAES-67.

E. CHARMLEY

Agriculture and Agri-Food Canada, Research Farm, Nappan, Nova Scotia

Introduction

Corn silage is a high energy feed source for ruminants. Being part forage and part grain, it has characteristics of both feed types and is a valuable component of dairy rations in regions where corn can be grown. Nutritionally, corn silage is lower in crude protein (CP) and higher in digestible energy (DE) than other forages. It also differs from other forages in that quality does not decline with advancing maturity. This is because the increasing amount of grain in the crop offsets the decline in digestibility normally associated with structural tissues (in the case of corn, stem). Compared to many crops corn is relatively easy to ensile. It is however a high-cost crop to grow, ensile and feed.

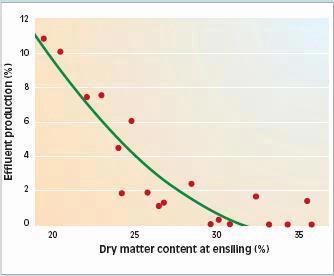

i) Moisture

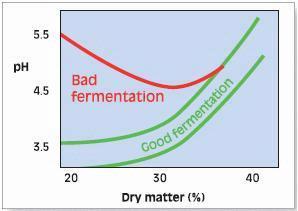

One of the most critical factors affecting the process of fermentation is the amount of water present in the crop at ensiling (Fig. 1). Silage microbes need water in order to thrive and multiply. That is why drying hay, for example, is effective at preventing most microbial growth. However, the amount of water is important in determining which microbes grow best. In silage, we normally quantify water in terms of dry matter (DM) content of the crop. Thus a low DM silage contains more water than a high DM silage.

Figure 1. Moisture and silage fermentation. The drier the silage the higher the pH can be for successful preservation.

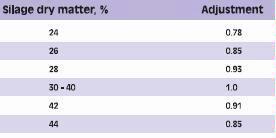

The wetter a silage, the more biological activity, of all kinds, there will be. This is not necessarily a good thing. Managing the ensilage process means creating an environment that favours desirable microbes over undesirable microbes. However if a silage is too dry, there will not be enough moisture to support sufficient microbial growth to produce the acids which reduce the pH and preserve the crop. Optimum crop DM content is between 25 and 50%, depending on the type of crop and storage system. In most forage crops, optimum DM content is reached by wilting prior to ensiling, a sometimes tricky business. However, in corn, the crop loses moisture as it matures and an optimum DM content of between 33 and 36% can be reached by waiting for the crop to mature (provided there are enough heat units). This feature, makes achieving the desirable DM content relatively simple in many silage growing areas. As a general guide, corn silage should be harvested when the milk line has descended 1/3 to 1/2 of the way from kernel crown to the base (see Corn Growth and Development section).

So why is wet silage undesirable? The wetter the crop the more active all bacteria become and the more food (substrate) is needed to sustain them. Since there is a limited amount of food reserves (substrate) in the harvested corn, beneficial bacteria have to compete with all the other types of bacteria. As crops dry, some types of bacteria are more affected than others. A major group of undesirable bacteria (the clostridia) are particularly susceptible to a scarcity of moisture. So by increasing the DM content we can weed out the bad bacteria from the good.

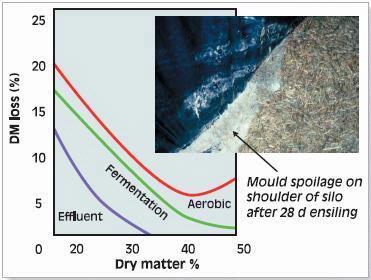

Wet silage is also problematic, because when it is piled in a bunker or, even worse, a tower, then pressure squeezes out water and many soluble sugars, proteins and minerals (Fig. 2). This silage effluent or run-off, not only represents a loss of nutrients, it is also a potent pollutant, having a very high biological oxygen demand (BOD). Upon entering waterways it causes eutrophication (rapid growth of biomass) and takes the dissolved oxygen out of the water. This will render a stream dead quite effectively.

Figure 2. Losses in a bunker silo.

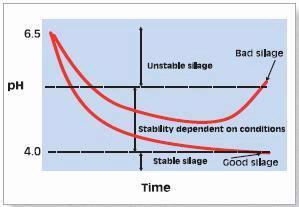

So why is dry silage undesirable? Silage that is too dry will not ferment enough to reduce pH to a level that will kill spoilage-causing yeasts, moulds and aerobic bacteria (Fig. 3). In wet silage, the spaces between the plant material are filled with water, but in dry silages they are filled with air. Also, dry material tends to be more springy and resistant to compaction. Under these conditions aerobic microbes predominate, particularly yeasts and moulds. These consume valuable nutrients, produce heat and thus cause spoilage. Heating is a particular problem, because as the silage heats up, then the yeasts and moulds proliferate even faster. Heating, which starts in the silo, tends to continue in the feed bunk, reducing feed intake and leaving large amounts of rejected feed.

Figure 3. pH decline and silage stability.

ii) Substrate

Silage micro-organisms need a supply of soluble carbohydrate or sugars. Most crops, including corn, contain between 3 and 10% of their DM as sugar. Corn usually has close to 10% of DM as sugar, which makes it a reasonably easy crop to ferment. These sugars are used up by the microbes to produce acids. Since the role of acids is to reduce pH, strong acids are needed; the strongest acid produced by bacteria is lactic acid. In a good fermentation, the goal is to have as much of the sugars converted to lactic acid as possible. Since the sugars are a finite resource, efficient use is paramount. Manipulating DM content will help to ensure that the desirable or homolactic bacteria will predominate in the microflora, producing lots of lactic acid to effect preservation.

Unlike most other silages, corn silage can actually have too much sugar! The unfermented sugars can remain at quite high concentrations even months after the crop has been ensiled. These sugars can be used by aerobic bacteria once the silo has been opened for feed-out. In this case the so-called (but misnamed) secondary fermentation can take place. It is not fermentation at all but aerobic respiration and produces a lot of heat and ultimately leads to spoilage of the silage.

The fact that corn silages can have too much substrate for the traditional fermentation, has led researchers to look at the possibility of using some of that sugar to produce acetic (vinegar) or propionic acid. (Manufactured propionic acid is often used as an additive help preserve high moisture grass hay.) Although these are weak acids and not very effective at reducing pH, they are quite effective at inhibiting aerobic microbes, particularly yeasts. Recent research has looked at the possibility of adding specific strains of bacteria to corn silage to produce these acids (See below).

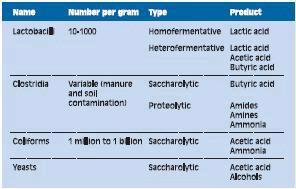

iii) Silage bacteria

When corn is harvested, plant surfaces are covered by a wide range of micro-organisms. These are known as epiphytic bacteria because they live on the host plant in a natural symbiosis. They are present in the thousands per gram of crop, but only a small fraction, namely the lactic acid bacteria (LAB), are of value in silage fermentation (Table 1). The numbers of lactic acid bacteria on corn at ensiling is low compared to the numbers needed for ensiling. After the crop is chopped and placed in the silo, the plant cells and aerobic bacteria continue to respire for a day or two and conditions in the silo become increasingly anaerobic. Eventually this aerobic respiration by the crop and microbes will use up all the oxygen in the silo. Then under these anaerobic conditions, the anaerobic bacteria, including the lactic acid bacteria, begin to proliferate. The anaerobic epiphytic bacteria now produce lactic acid, as well as a range of other acids, alcohols and related compounds from sugar present in the crop.

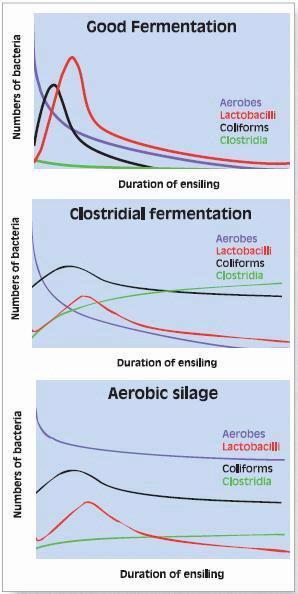

In the initial phase of ensiling, competition for substrate by the various types of bacteria is intense. Eventually, however, conditions will begin to favour one or another group. Under conditions of optimum moisture and substrate availability, the lactic acid bacteria will predominate (Fig. 4). The more rapidly they can proliferate, the more rapidly the pH drops and under these conditions lactic acid will be the dominant organic compound produced. Good silage fermentation will ensue.

Figure 4. Change in population over time of 4 bacterial groups in good fermentation (top), clostridial fermentation (middle), aerobic fermentation (bottom).

When conditions are sub-optimal for LAB, they may never dominate the fermentation. For example, in wetter silages the Clostridia may predominate (Fig. 4). These bacteria are always present on the standing crop but are particularly numerous in soil and manure. Although manure is a potential source of contamination in corn, the long interval between manure application and harvest and the fact that corn does not normally come into contact with the ground during harvest means that clostridial contamination from manure is unlikely. Another group of bacteria which sometimes come to dominate silage fermentation are the ‘coliform’ bacteria, or enterobacteria. These tend to dominate in silage when the rate of pH decline is slow or where the final pH is high. These bacteria produce a range of organic acids and alcohols and are not effective at preserving silage. They are also associated with the production of endo-toxins and ammonia. High levels of ammonia in drier silages are indicative of fermentation dominated by coliform bacteria.

Filling the Silo

i) Management

No matter what crop or system of ensiling is used, the single most important determinant for making successful silage is good management at the time of ensiling. The various aids to making good silage do not substitute for good management practices, and in fact are wasted if not used in association with good management.

Understanding the principles of ensiling helps the farmer understand the critical control points for success. Since ensiling is an anaerobic process, rapid and effective filling and sealing of the silo is critical. It is essential to minimize the amount of air that gets into the silo. How this is done will depend on the type of silo used.

Silos come in many forms. The ‘Cadillac’ of silos is the gastight, glass-lined upright silo, which became very popular 20 to 30 years ago. These are expensive, but effective. The silo walls are totally airtight, and the silo is filled from the top. The weight of the crop provides the pressure for packing. Without any ingress of air to the system, the silage quickly becomes anaerobic and good fermentation usually results.

This system is generally best used in silages of 40% DM or higher. Corn silages, which are usually ensiled below this threshold, may have too much moisture. The pressures exerted in such a silo will produce silage effluent (also known as seepage or run-off ), which will either collect at the base or leak out of the silo. In either case, this is bad. The higher moisture will sour the silage at the base of the tower if it remains in the silo and the effluent poses an environmental threat. To maintain an anaerobic atmosphere during unloading, these silos typically empty from the bottom.

The concrete stave silo, is a less costly and less elaborate version of the upright tower. The principle behind achieving anaerobic conditions is the same, although the system is slightly less effective. These silos are unloaded from the top. It is critical to remove 10 –15 cm (4 to 6 in) of silage a day so that the silage is fed before it begins to deteriorate. These silos are relatively common, and those filled with corn silage are often seen weeping effluent from the sides in the lower portion of the silo — a clear sign the silage was too wet.

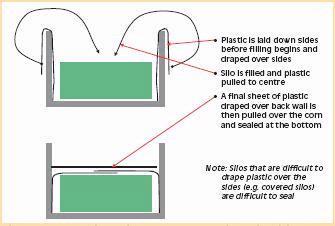

Bunker silos are effective. Although corn silage can be successfully stored in towers, the crop is eminently suited to bunker silos because there is less pressure to cause seepage in a bunker silo. To be effective, bunker silos have to be filled quickly and sealed effectively because of the large surface area.

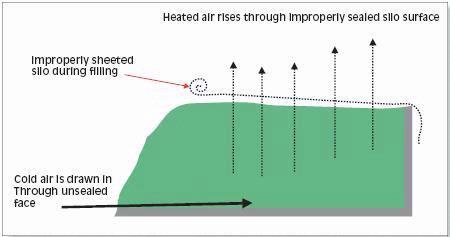

Sealing is particularly crucial for corn silage because it contains a lot of sugar for microbes to grow on. If air is present, the sugars are used by aerobic organisms causing heating. Plant and aerobic microbial respiration using up the sugars produce heat warming the air and causing it to rise while bringing down cool air filled with fresh oxygen (called flue effect). This stimulates more aerobic activity and the cycle continues (Fig. 5).

Figure 5. Transverse section of a silo during filling, showing “flue effect”.

Compared to grass silages, corn silage is easy to pack, especially when well chopped or ‘processed’ (see Processing Corn Silage section). It tends to pack well, up to a point, beyond which further packing has little added benefit. Forage harvesters should be set for a theoretical chop length of 6–9 mm (¼ to 3/8 inch). About half the silage should be as particles 13 mm (½ in) long, with the rest somewhat longer. Excessive long particles indicate that the chopper needs sharpening and re-setting.

ii) Silage inoculants

Conventional microbial inoculants work by adding a fairly large amount of lactic acid producing bacteria—usually 100,000 organisms (or cfu) per g of crop in North America and 1,000,000 cfu per g of crop in Europe. The hope is, that these relatively large numbers of homolactic bacteria will be able to quickly dominate the natural, less efficient, lactic acid bacteria, and so produce a better silage. In many cases this does happen.

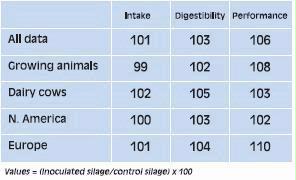

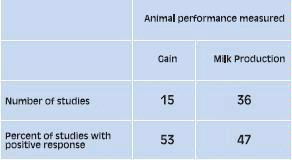

Research has shown that on average silage inoculants will result in small improvements in milk or beef production. Table 2 shows the results of a survey the author conducted in 1994. This survey considered all silages, not just corn silage. We found a small benefit in digestibility and intake. Combined, these resulted in a 2 to 10% improvement in animal performance. Since that time, it is reasonable to conclude that silage inoculants have improved, however more recent reviews of the literature still reach similar conclusions. Nevertheless, products are priced to ensure an economical return, on the average. However, in about . of cases, the additive will have no discernable effect on the silage fermentation, and about half the time they will have no effect on animal output (Table 3).

Table 2. Animal response to silage inoculants. Results of a survey by the author (1994).

Table. 3. Animal response to silage inoculants. Results of a survey by Kung and Muck (1990 to 1995)

More recent commercial additives usually contain a cocktail of microbial strains and types. By providing a complex mixture, manufacturers claim better success. Some bacteria, such as Streptococcus or Pediococcus, will be active very early on in the fermentation, when the pH is still quite high and there is still some oxygen in the system. Others, like the Lactobacilli, will play a longer term role, continuing to reduce the pH once the “starter bacteria” have died off. However, single strain inoculants can still be very effective. In choosing an inoculant, the buyer should look for products that are from a recognizable company and have a proven track record. Generally, these have been vigorously researched and newer, more effective strains are continually being developed. Products with complicated formulations may not be any better and even if the bacterial name is the same in two different products, the strain will probably not be. Just as all Holstein cows are not created equal, neither are all strains of Lactobacillus.

Additives manufactured specifically for corn silages often contain enzymes as well as microbial inoculants. Corn silage contains a large proportion of starch, as a result of having a high grain component. By adding amylase enzyme that can convert starch to sugar, the expectation is that this will improve fermentation. While this approach may give some added benefit, the evidence for this is not strong. Given that corn silage already contains adequate sugars for fermentation, production of more may actually be detrimental. Additional sugar may serve as fuel for yeasts and moulds, particularly during feed-out.

Emptying the silo

i) Bunker management

As already mentioned, corn silage is susceptible to heating and spoilage during feed-out. So one of the main goals of bunk management is to work to reduce the opportunity for heating at every stage of the operation. The silo, whether tower or bunker, should be designed such that enough silage is removed each day to keep the face moving back at least 4 to 6 inches a day, on average. The more susceptible a silage is to deterioration, the faster it should be removed from the silo. The following steps are recommended when emptying the silo:

- Minimizing disturbance to the silo face is essential. This prevents air getting further into the silage. Silage cutters (also known as shear grabs or block cutters) are an excellent tool for reducing waste at feed-out. They should however be well maintained to ensure it cuts and doesn’t tear.

- Keeping the faces clean and free of spoiled silage is also essential. These can become reservoirs of heat and spoilage organisms if left close to the silo.

- Plastic should only be removed from the silage as the silage is used.

ii) Bunk management

Cleanliness is again crucial to minimize heating in the feed bunk. Old silage should be removed daily if possible. Heating silage left in the bunk, will cause the new feed to heat all the faster. These tips are particularly critical in hot weather.

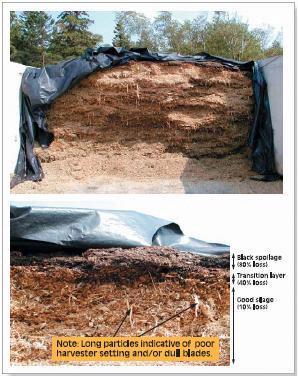

Figure 8. Top: smaller bunker silo (12 ft face) designed to ensure face moves back 1 ft per week during summer feeding — minimal signs of spoilage. Bottom: surface spoilage on the same silo — close up view.

Concluding remarks

Corn silage is an excellent feed for high producing ruminants. Although making silage is always a potentially risky business, the risks with corn silage are often less than with grass and legume silages. The crop is naturally at the correct DM content for ensiling and almost always has ample sugars to ensure a satisfactory fermentation. Perhaps the biggest challenge with corn silage is controlling heating and aerobic deterioration. However, careful management both when filling and emptying the silo can reduce the risks. New silage inoculants just coming onto the market may one day prove to be very beneficial in controlling spoilage, thus reducing the risk still further.

Processing Silage Corn on Particle Size, Packed Density, and Silage Fermentation

J. Harrison and L. Van Wieringen

Department of Animal Sciences, Washington State University, Puyallup, WA

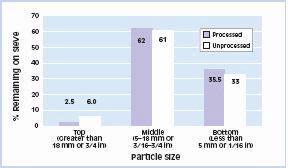

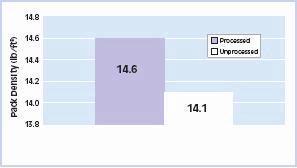

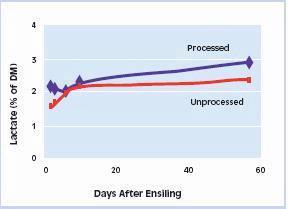

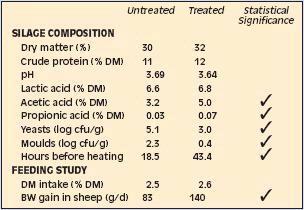

Processing silage corn results in forage with smaller particle size. Using the Nasco or Penn State forage particle separator we found that processing reduces the percentage of particles remaining on the top sieve (greater than 18 mm or ¾ in) and increases the percentage of particles remaining on the middle (between 5–18 mm or 3…–¾ in) and bottom sieves (Fig. 1). The decrease in particle size increases how densely corn silage is packed in silos, hence the porosity and rate of air infiltration, which ultimately determines the amount of spoilage that occurs at the time of feedout. Many studies have shown that processing corn silage increases wet pack density in the silo over a range of maturity (one-third milk-line to physiological maturity) and theoretical chop lengths (6–13 mm or ¼–½ in) (Fig. 2). The only exceptions were 2 experiments where the chop of the corn silage was long (10–38 mm or 2..–1½ in). Based on this, we expected that processed silage would undergo faster silage fermentation and result in more lactic acid (Fig. 3) and a lower pH (Fig. 4). However, in the majority of cases, we observed that mechanical processing did not enhance lactic acid production or pH decline at first. It appears that some of the mechanically processed corn silages had increased buffering due to the exposure of cell contents to the forage mix. This likely resulted in the higher pH of processed silage during fermentation in the silo. The processed silage did have lower pH and more lactic acid after several weeks in the silo.

Figure 1. Particle size distribution of processed and unprocessed corn silage (theoretical chop length 12 mm or 1/2 in).

Figure 2. Effect of processing on wet pack density (for kg/m3 multiply lb/ft3 X 16.1).

Figure 3. Effect of processing on increase of lactate during ensiling of corn silage harvested at blackline (greater than 40% dry matter).

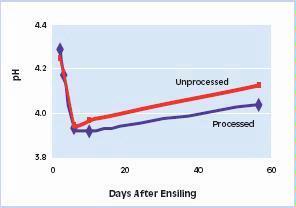

Figure 4. Effect of processing on change of pH during ensiling of corn silage harvested at blackline (greater than 40% dry matter).

Aerobic Stability – Processed Corn Silage

J. Harrison and L. Van Wieringen

Department of Animal Sciences, Washington State University, Puyallup, WA

The greater wet pack density for processed corn silage tends to improve aerobic stability at feedout. Aerobic deterioration occurs as a result of microbial activity. The factors that influence deterioration include: oxygen (exposure time), composition of the microbial population, substrate type, and temperature. Yeasts are usually the initial cause of aerobic deterioration. As lactic acid (the major end product of silage fermentation) and other residual sugars are combusted and used by yeast, the temperature starts to rise. Aerobic stability can be measured as: 1) number of hours until temperature of corn silage increases 2°C (3°F) above ambient, 2) number of hours until corn silage reaches peak temperature, and 3) maximal temperature rise above ambient.

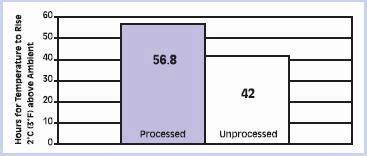

In our studies, processing of corn silage enhanced aerobic stability. While it took longer for processed corn silage to heat by 1.5°C (3°F) (Fig. 1), both silages reached maximum temperature in about the same amount of time. This indicates that the processed corn silage was more stable in an aerobic environment early on (i.e. took longer to start heating) due to greater pack density that limited exposure of processed corn silage to oxygen during the storage phase. However, once the silages were exposed to air there was nothing particular about the processed corn silage that inhibited growth of aerobic microorganisms.

Therefore, once they began to grow, the microorganisms in both silages multiplied causing both silages to heat at the same rate and the same amount (ranging from 6.4° to 13.1°C or 11.5° to 23.6° F).

Figure 1. Aerobic stability of processed and unprocessed corn silage.

Silo tips

J. Harrison and L. Van Wieringen

Department of Animal Sciences, Washington State University, Puyallup, WA

The amount of packing time and the thickness of the silage as it is layered in to the silo interact to affect silage density. It is desirable to layer the forage into a bunker silo at depths of 15 cm (6 in) or less and pack to a rate of 2-3 minutes per tonne (or Ton) of forage or 300–600 hrkg per tonne (600–800 hr-lb per T) of wet forage. When forage delivery to the silo is in the range of 40 wet tones (or Tons) per hour these rates are achievable and realistic. Delivery rates greater than this will require large packing tractors and likely multiple packing tractors. Common recommended feed-out rates are 15 cm (6 in) per day, but more is recommended in hotter weather. It is best not to “buck” into the silage mass when removing silage as this allows channels for the entry of air back into the silage mass.