J. Oenema and J. Verloop

Plant Research International, Wageningen, the Netherlands

In the Netherlands, inputs of nutrients on dairy farms via fertilizers, legumes and purchased feed by far exceed the outputs in milk and meat. Eventually, the excess nutrients are emitted to the environment, a problem which is especially acute in sandy regions. Government policy aims at reducing these losses to ‘acceptable’ levels. Research is being carried out in a model dairy farm called ‘De Marke’, located in the eastern sandy area of the Netherlands, to generate information and explore opportunities for reducing losses. The objective of the ‘De Marke’ project is to design and operate an economically viable dairy farming system that meets strict environmental standards, taking into account societal objectives with respect to animal welfare, nature and landscape.

Dairy farming is characterized by the combination of plant and animal production within one farming system. In animal production, part of the nutrients from feed is ‘transformed’ into dairy and meat products while the remainder is excreted in manure. The manure is applied to the field as an input for crop production. The harvested crops are used as feed for the animals, thus closing the cycle. Improved nutrient management through the cycle is characterized by a higher proportion of the nutrients being transferred to products and lower losses to the environment.

Photo 1 ‘De Marke’ farm in the Netherlands (Wageningen UR).

Photo 2 Sampling corn silage at ‘De Marke’ farm in the Netherlands

(Wageningen UR).

Farming System

In order to design a suitable farming system for ‘De Marke’, first input-output relations were quantified, combining process knowledge and expert judgment. For the animal component of the system, this included the relation between milk production and feed requirements (both quantity and quality); for the plant component the relation between crop production on the one hand and nutrient (fertilizer) and water requirements on the other. On the basis of these relations various farm configurations were considered. The most interesting design from the research point of view was implemented in 1992 in the ‘De Marke’ farm. The farming systems on ‘De Marke’ are under continuous development (Table 1).

|

Table 1. Characteristics of crops, animals and farm plan of experimental farm ‘De Marke’. |

|||||

|

|

1993 |

1996 |

1999 |

2002 |

Average ’93-’02 |

|

Milking Cows # |

82 |

77 |

77 |

77 |

78 |

|

Young Stock # |

66 |

58 |

62 |

53 |

57 |

|

Stock density AU/ha (Au/ac) |

1.9(0.8) |

1.7(0.7) |

2.0(0.8) |

1.7(0.8) |

1.8(0.7) |

|

Milk Yield / cow (kg) |

8005 |

8791 |

9175 |

8752 |

8632 |

|

Milk Yield / cow (lb) |

17,611 |

19,340 |

20,185 |

19,254 |

18,990 |

|

Milk fat content % |

4.39 |

4.31 |

4.05 |

4.33 |

4.3 |

|

Milk protein content % |

3.49 |

3.47 |

3.44 |

3.35 |

3.4 |

|

Land Area ha (ac) |

|||||

|

Grass |

30.6(76) |

29.2(72) |

31.9(79) |

31.9(79) |

31.2(77) |

|

Silage corn |

13.1(32) |

20.2(50) |

14.9(36.8) |

9.9(24) |

13.5(33) |

|

Ground ear corn silage |

5.8(14) |

7.1(18) |

5.1(12.6) |

4.7(11.6) |

6.8(17) |

|

Fodder beet |

6.1(15) |

0 |

0 |

0 |

1.5(4) |

|

Triticale silage |

0 |

0 |

0 |

8.4(21) |

2.2(5) |

|

Farm area |

55.6(137) |

56.5(140) |

51.9(128) |

54.9(136) |

55.1(136) |

| *animal unit:milking cow = 1AU; young cow >1 year old = 0.439 AU; young cow < 1 year old = 0.22 AU | |||||

Land Use

The 55 ha (136 ac) of land comprise three parcel types:

- 11 ha (27 ac) of grassland (permanent pasture), located close to the farm buildings

- 30 ha (74 ac) (home parcel) – alternating three years of grassland with three years of corn

- 14 ha (35 ac) (field parcel) – alternating three years of grassland with five years of corn.

The parcels near the barns can be irrigated whereas the field parcel which is farther away from the farm buildings cannot be irrigated. Consequently, grazing intensity is higher on the permanent pasture and the home parcel than on the field parcel. There are several advantages for grass-corn rotation over continuous corn: soil organic matter content is maintained at a higher level than under continuous corn, with positive effects on moisture retention capacity and rooting; fertilizer strategy can be targeted to the rotation; weed problems are mitigated; and yields of corn are on average 10% higher in rotation than under continuous cropping.

Italian ryegrass planted between corn rows at ‘De Marke’farm in the Netherlands (Wageningen UR)

A little more than half the land area is used for grassland; the remainder is now in use for corn (whole silage and ground ear-corn silage) and triticale silage. The proportion of the land used for corn and triticale is higher at ‘De Marke’ than on most commercial farms on sandy soils in the Netherlands.

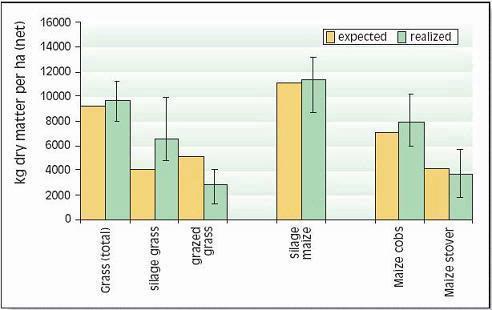

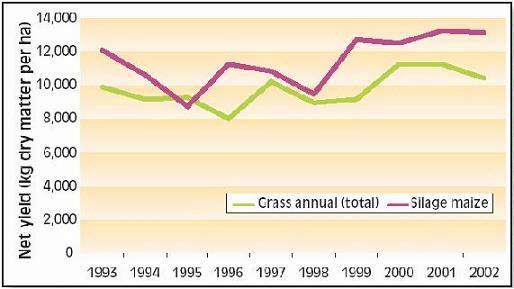

Corn silage yields are consistently higher than those of grass (Figs. 1 and 2). Moreover, on the droughtsensitive soils of ‘De Marke’, less irrigation is required for corn than for grass (200 vs. 350 L of water/ kg dry matter or 12 vs. 20 gal/lb dry matter). Hence, a larger proportion of corn both reduces the usage of ground-water for irrigation and the requirements for purchase of feed. Furthermore, a high proportion of (energy-rich and low protein) corn in the feed ration results in lower nutrient contents in manure.

Figure 1. Average net yields of grass (excluding grazing- and harvest losses) and silage corn (kg dry matter per ha) at ‘De Marke’ in the period 1993-2002 (for lb/ac, multiply by 0.9)

Part of the corn crop is harvested as ground ear-corn silage, a product that has proven its value as a substitute for purchased concentrate. The ground ear-corn and the corn stover are harvested at the same time but separately with a specially designed harvester. Because corn stover contains little energy, protein and potassium, but high levels of cell walls which are partly digestible, it is an excellent component (with fall grass silage) for dry cow and pregnant heifer rations.

Since 2000, some corn was replaced with triticale (for silage) under-seeded to a grass/clover mix in the final year of both rotations (Table 1). This change was made because it was felt that triticale would lower nitrate concentration in groundwater relative to corn.

Manure and Fertilizer

Storage, handling and timing of application of manure all aim at maximizing utilization of nutrients by the crop in order to minimize use of chemical fertilizer. For phosphorus, the principle of equilibrium manure application (i.e. total nutrient application in manure should not exceed nutrient export in crops) is used. For the crop rotations, the equilibrium rate is based on a full rotation cycle.

The basic application rates for N are 250 kg/ha (230 lb/ac) for grass and 100 kg/ ha (90 lb/ac) for corn, including the inorganic N in the slurry. Fertilizer rates are determined per field, taking into account the crop, soil moisture-supplying capacity, phosphorus status of the soil and N-supply from ploughed-in sod and green manure. Slurry rates are based on crop N requirements for corn and crop P requirement for grassland. About 80% of all slurry is applied to grassland. Fertilizer application starts on March 1 for grassland and just before sowing (early May) corn.

Cover (relay) Crop

A disadvantage of corn is that its nutrient uptake virtually ceases after the beginning of August. In late summer and autumn, mineralization adds to the soil N that the crop doesn’t take up at this time. To solve this problem, a catch crop of Italian ryegrass is sown between the corn rows, about six weeks after sowing.

Following (early) corn harvest, the ryegrass continues growing and takes up the residual N. Such a catch crop is very effective in reducing environmental impact and is easy to include in farm management.

Photo 4 & 5 Harvesting corn underseeded with Italian ryegrass and growth of cover crop in fall at ‘De Marke’ farm in the Netherlands (Wageningen UR)

Yields

Yields of grass and silage corn in the period 1993-2002 were above expectation (Fig. 1) but year-to-year variation was very high (Fig. 2). Corn yields were mainly determined by soil moisture status during grain set. Drought at any other time reduces yield of grass more than corn so low annual grass yields resulting from moisture deficits can coincide with reasonable corn yields. In the years with favorable moisture supply (1993, 1997, 1999, 2000, 2001 and 2002), average grass and corn yields exceeded 10,000 kg/ha. In contrast, spring of 1998 was extremely wet, which resulted in high mineral N losses, especially in corn, and consequently low yields.

Yields of the ground ear-corn silage were higher than expected, and those of stover lower, but stover yields have increased in recent years since the performance of the harvester was improved.

Figure 2. Year-to-year variation in net yields of grass (excluding grazing- and harvest losses) and silage corn at ‘De Marke’ (for lb/ac, multiply by 0.9)

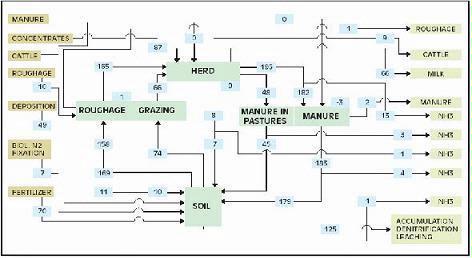

Nutrient Flows

The total nutrient cycle comprises the components herd, manure, soil and crop (roughage and pasture grass). These components can be considered the links in the cycle. The nutrient balance between components shows relative efficiency of nutrient utilization, which helps identify weakest links. Fig. 3 shows the average N cycle for ‘De Marke’ for a period of 10 years (1993 – 2002).

Figure 3. Nitrogen cycle (kg N per ha) of experimental farm ‘De Marke’ averaged over the period 1993 – 2002 (for lb/ac, multiply by 0.9).

The surplus nutrients of the farm can be partitioned into ammonia volatilization and denitrification (N only), and accumulation in soil organic matter, runoff and leaching (N and P) (Table 2). The absence of surface water at ‘De Marke’ means that runoff does not play a role. Average annual surplus over the period 1993 – 2002 was 144 kg N /ha (130 lb/ac) and 3 kg P2O5 /ha (2.5 lb/ac). Since 2000, some changes have been implemented in the design of the farming system (less grazing, lowering the fertilization level) resulting in a lower N surplus in 2002 of 117 kg /ha (105 lb/ac).

Comparison of the nutrient balance of ‘De Marke’ with that of the ‘current average’ farm (on sandy soil in the middle of the 1990s with a milk quotum equal to that of ‘De Marke’) shows that at ‘De Marke’ less fertilizer and feed were purchased. In other words, the realization of very high nutrient utilization efficiencies in animal nutrition and crop cultivation allows similar milk production at much lower input levels. This can be considered the most important aspect of the farming system ‘De Marke’.

| Table 2. A comparison of nutrient balance (N and P2O5) of the ‘De Marke’ averaged over the period 1993 – 2002, and for the year 2002, with the nutrient balance of the average farm in the Netherlands (see text for explanation) in the middle of the 1990s (for lb/ha, multiply by 0.9). | ||||||

|

Nitrogen (kg N/ha)kkk |

Phosphate (kg P2O5/ha) |

|||||

|

De Marke |

Average |

De Marke |

Average |

|||

|

|

93-02 |

2002 |

Dutch Farm |

93-02 |

2002 |

Dutch Farm |

|

INPUT |

|

|

|

|

|

|

|

Concentrates |

86 |

87 |

125 |

28 |

29 |

49 |

|

Roughage |

8 |

0 |

20 |

3 |

0 |

2 |

|

Chemical fertilizer |

64 |

35 |

242 |

1 |

0 |

41 |

|

Organic manure |

0 |

0 |

50 |

0 |

0 |

29 |

|

Biological N fixation |

11 |

27 |

0 |

|

|

|

|

Animals |

0 |

0 |

0 |

0 |

0 |

|

|

Deposition |

49 |

49 |

49 |

2 |

2 |

2 |

|

Miscellaneous |

5 |

5 |

0 |

0 |

1 |

0 |

|

Total |

223 |

203 |

486 |

34 |

32 |

124 |

|

|

|

|

|

|

|

|

|

OUTPUT |

|

|

|

|

|

|

|

Milk |

66 |

64 |

64 |

24 |

23 |

24 |

|

Animals |

9 |

8 |

14 |

6 |

5 |

9 |

|

Roughage |

1 |

0 |

0 |

0 |

0 |

0 |

|

Organic Manure |

1 |

0 |

0 |

0 |

0 |

0 |

|

Total |

77 |

72 |

78 |

30 |

28 |

34 |

|

Changes in Stocks |

2 |

14 |

0 |

1 |

1 |

0 |

|

Surplus |

144 |

117 |

408 |

3 |

3 |

90 |

A.M. JOHNSTON¹ and R. DOWBENKO²

¹ Potash & Phosphate Institute of Canada, Saskatoon, Saskatchewan; ² Agrium Inc., Calgary, Alberta.

Plants require 16 nutrient elements for their growth. Three of the nutrient elements (carbon, hydrogen and oxygen) are derived from air and water. The other 13 are normally obtained by the plant from the soil or applied as amendments (fertilizer, manure, etc.) if they are inadequate or unavailable in the soil. Nitrogen (N), phosphorus (P) and potassium (K) are required by plants in relatively large quantities and are most frequently required as soil amendments for maximum crop growth. In fact, the first three numbers on fertilizer products (e.g., 18-18-18) are the percentages of N, P (expressed in oxide form as P2O5) and K (also expressed as an oxide as K2O). For this discussion, these three nutrients are grouped as “primary” nutrients. Sulphur (S), calcium (Ca) and magnesium (Mg) are required by the plant in moderate quantities and are grouped as “secondary” nutrients. The remaining seven nutrients are grouped as “micronutrients” as they are required in small quantities or applied to crops less frequently. Comparative amounts of these nutrients are shown in Table 1 for a corn crop yielding 18.7 t/ha dry matter. This constitutes the amounts of these nutrients that would be removed from the field if the corn is used as silage.

|

Table 1. Comparison of Quantities of 13 Essential Nutrients typically found in a Corn Crop Yielding 18.7 t/ha dry matter (9 T/ac; for lb/ac multiply by 0.9) |

|||

| Nutrient |

kg/ha |

Nutrient |

kg/ha |

| Nitrogen (N) |

240 |

Chlorine (Cl) |

110 |

| Phosphorus (P) |

44 |

Iron (Fe) |

3 |

| Potassium (K) |

200 |

Manganese (Mn) |

0.6 |

| Zinc (Zn) |

0.6 |

||

| Sulphur (S) |

34 |

Copper (Cu) |

0.2 |

| Calcium (Ca) |

45 |

Boron (B) |

0.1 |

| Magnesium (Mg) |

56 |

Molybdenum (Mo) |

> 0.1 |

Primary Nutrients

Nitrogen (N)

Nitrogen is necessary for making chlorophyll and is directly involved in photosynthesis. Each molecule of chlorophyll contains four N atoms surrounding a magnesium (Mg) atom at the core. All proteins and enzymes contain N in the form of amino acids. Nitrogen is also a component of vitamins. Increasing N supply enhances plant production of carotene (a precursor to vitamin A), the B vitamins (riboflavin, thiamin, and nicotinic acid), and cytokinin (a plant growth hormone).

Nitrogen deficiency in young corn reduces chlorophyll production and causes the entire plant to be pale and yellowish green, with spindly stalks. Later, V-shaped yellowing may appear on the tips of leaves. Since N is mobile within the plant, yellowing begins on the older lower leaves and progresses up the plant as the N is moved up to the newer growing tissues. When N is deficient, the production of chlorophyll and enzymes for photosynthesis is limited, slowing the supply of energy and reducing plant vigour. Also, the root system becomes less prolific, slowing uptake of other nutrients (Table 2). Note the small increase in K concentration. Nitrogen tends to increase K uptake, but only when soil K levels are high. When soil K is low, added N stimulates growth dilution of the K in the plant.

Corn takes up N as inorganic nitrate (NO3 -) and ammonium (NH4+) ions. Ammonium is rapidly converted to nitrate in most soils, therefore, most N uptake is in the nitrate form. However, certain corn hybrids prefer ammonium. Taking up N as ammonium saves the plant a great deal of energy which is required to convert nitrate to ammonium before it is used for protein synthesis. Too much ammonium can be toxic to plants.

|

Table 2. Example of how nitrogen application can increase the concentrations of other nutrients in ear leaf at silking or anthesis (adapted from Illinois and Ontario university data) |

|||

|

Nutrient |

Zero N |

With N |

Increase |

|

Nitrogen (%) |

2.45 |

3.20 |

31% |

|

Phosphorus (%) |

0.22 |

0.29 |

30% |

|

Potassium (%) |

1.93 |

1.96 |

2% |

|

Calcium (%) |

0.88 |

0.90 |

2% |

|

Magnesium (%) |

0.43 |

0.48 |

12% |

|

Zinc (ppm) |

20 |

29 |

45% |

|

Boron (ppm) |

9 |

12 |

34% |

|

Copper (ppm) |

8 |

12 |

44% |

|

Grain Yield, kg/ha* |

5707 |

7212 |

1505 (26%) |

Phosphorus (P)

Although P is not present in the plant in large quantities, it is involved in many critical metabolic functions that occur in the plant’s cells. It influences the activity of many enzymes, is a carrier of energy within the cell and can also store energy as in phytin. Because of the ability of inorganic P compounds to dissociate into various forms, it is an important component to buffer the pH within the cell. It is a component of a variety of organic molecules, such as phospholipids, which are involved in a range of activities and functions. Phosphorus is important for photosynthesis, maintenance and transfer of genetic code, development and growth of new plant cells, and germination and formation of seed.

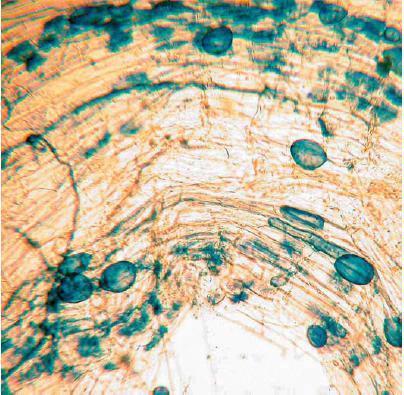

Phosphorus deficiency usually appears when plants are young. Young plants develop shoots faster than roots, particularly when the air is much warmer than the soil, causing a high P demand per unit of root length (See Applying Starter Fertilizer section). Often soil solution P concentrations are inadequate to meet these high requirements, leading to buildup of carbohydrates and sugars, which causes a dark green or reddish-purple leaf color. Extreme symptoms include spindly stalks which are either barren or have twisted ears with incomplete grain fill. Inadequate P, even in seedlings, frequently delays maturity. Phosphorus enters the corn plant through root hairs, root tips, and the outermost layers of root cells. Beneficial fungi, called mycorrhizae, also enhance P uptake (see Early Phosphorus Nutrition in Corn and the Role of Mycorrhizae section).

Phosphate fertilizers typically contain soluble forms of P that are immediately available to plants. However, soluble P in soil reacts with iron (Fe), aluminum (Al), calcium (Ca), and magnesium (Mg) forming new compounds that are less plantavailable, a process called “fixation.” Maintaining the soil pH between 6 and 7 usually maximizes P availability. The fixed P may eventually become plant-available but this can take months or years. Phosphorus is also contained in soil organic matter and manure, and is gradually released as plant-available forms in a process called mineralization. The P used by a corn crop therefore comes from fertilizer and manure applied for that crop and from such materials applied in previous years.

Potassium (K)

Potassium is involved in photosynthesis, conversion of sugars into energy storage compounds such as starch, conversion of amino acids into proteins, the activation of over 60 enzyme systems, and regulation of leaf pore function. In addition to these factors increasing yield and quality of silage corn, K improves disease resistance, N use efficiency and water utilization by preventing excessive respiration. Potassium in cell water helps protein molecules keep their conformation or shape and maintain their activity.

Potassium deficiency is not always evident visually and can be masked by other crop stress symptoms. Look for leaf discoloration, with older leaf edges turning yellow then brown while the midrib stays green. Conditions that may indicate K deficiency include: thin stands due to poor seedling vigor and disease, slow growth rate and poor N response due to reduced enzyme activity, injury due to stress and leaf diseases, delay of silk emergence by up to one week, stalk lodging due to breakdown of internal stalk tissue and invasion by stalk rot, and chaffy, loose-grain ears and poor grain fill near the ear tip.

Potassium is provided both from the soil’s nutrient reservoir and from fertilizer. The amount of K needed by a corn crop is very site-specific, varying between fields and within fields. The fertilization program should consider several factors that affect availability and uptake of K: soil analysis, nutrient requirements for the target yield, previous crop management practices, cultural practices (tillage) and climatic conditions which interact with K availability and uptake by corn. Soil testing provides a measure of the soil’s K nutrient reserves and an estimate of likely crop response to applied fertilizer. Because K is relatively immobile in most soils, no more than 50 to 60% of fertilizer K can be absorbed by corn during the season of application, even when soil supplies are low and growing conditions are favorable. In the long term, K rates should be such that soil test K is built to and maintained at levels that ensure maximum economic yields.

Timing of Potassium Uptake

The relative amounts of nutrients taken up at each stage of growth will differ and is best shown by uptake of major nutrients and dry matter production during 25-day periods which represent 5 different stages of growth (Table 3). Nearly 75% of the nitrogen, 65% of the P and 85% of the K used by the crop are taken up by the time the ears are tasseling, which is usually about the mid-point of the growing season.

Corn takes up very little N in the first month after planting, but once the crop reaches a height of about one foot uptake becomes very rapid (Table 3). Nitrogen supply before silking can affect the number of kernels set in the ear. Most corn hybrids take up less than 30% of their total N after silking. However, newer hybrids with “stay-green” and multileaf traits take up 40% or more of their N after silking. Removing nitrate from the soil late in the season reduces the amount left in the soil that may be lost over winter (see Post Harvest Nitrate Test section).

When does corn need K? Every day. The amount increases by growth stage until seedlings become fully mature plants. Potassium must be available early for optimum corn development because over 70% of the total K requirement must be in the plant by silking stage, or about 65 days after planting (Table 3). The peak rate of absorption per day occurs just prior to silking. Uptake is slower but not less important during the critical period of grain formation. Uptake per unit of root length is also an important expression of K requirement. Corn grows shoots faster than roots during early growth stages. Therefore, soils sometimes fail to meet the high requirement of each root segment and K deficiency results during the vegetative growth stage. For these situations, K supplemented by a side dress application prior to silking can improve crop productivity.

Balancing N and K

The right balance of N with K improves grain and silage yields, boosts forage quality, improves input use efficiency and provides better protection of groundwater. For example, application of 160 kg/ha (145 lb/ac) of K improved the quality of N-fertilized corn silage by reducing fermentation losses by 5 percent, increasing the carotene content six-fold and nearly tripling total protein production. Application of K also improved N-use-efficiency, helping the corn plants capture nearly 25 percent more N (Table 4) thus lowering the risk of unused N moving down to ground water.

|

Table 3. Example of the Pattern of Uptake of Primary Nutrients by a Corn Crop |

||||||

|

Growth Stage |

Seedling |

Rapid Vegetative |

Silking |

Grain Fill |

Maturity |

Total |

|

(days) |

(1-25) |

(26-50) |

(51-75) |

(76-100) |

(101-125) |

(1-125) |

|

Amount of growth and nutrient uptake during each growth stage (kg/ha)¹ |

||||||

|

Dry Matter |

524 |

3,597 |

6,369 |

6,745 |

1,499 |

18,734 |

|

Nitrogen (N) |

19 |

84 |

75 |

48 |

14 |

240 |

|

Phosphorus (P) |

2 |

12 |

16 |

11 |

3 |

45 |

|

Potassium (K) |

18 |

88 |

62 |

28 |

4 |

200 |

|

Proportion of uptake during each growth stage (%) |

||||||

|

Nitrogen (N) |

8 |

35 |

31 |

20 |

6 |

100 |

|

Phosphorus (P) |

5 |

27 |

36 |

25 |

7 |

100 |

|

Potassium (K) |

9 |

44 |

31 |

14 |

2 |

100 |

|

Table 4. Example of the Influence of K on Corn Grain Yield and N Efficiency |

|||

|

K applied |

Grain |

N-Efficiency |

N Uptake |

|

(kg/ha)¹ |

(kg/ha)¹ |

(kg grain/kg N) |

(kg/ha)¹ |

|

0 |

8,340 |

49 |

194 |

|

50 |

8,780 |

52 |

204 |

|

100 |

10,347 |

62 |

240 |

|

¹ For lb/ac multiply by 0.9 |

|||

Secondary Nutrients

Sulphur (S)

Sulphur is required by plants for the synthesis of certain amino acids (cysteine and methionine), protein formation, and photosynthesis. Symptoms of S and N deficiency are often confused. Sulphur is immobile within the plant and does not readily move from old to new growth. Hence, with S deficiency, yellowing symptoms first appear in younger leaves, unlike N deficiency, where yellowing appears on the older leaves first. Both N and S deficiencies may appear as stunted plants, with a general yellowing of leaves.

Sulphur has been overlooked in many soil fertility programs. But recently, increased crop yields, reduced deposition of atmospheric S, increased use of high analysis fertilizers, and greater awareness are contributing to increased requirements for S fertilizer applications. Most S in the soil is bound in the organic matter and cannot be used by plants until it is converted to the soluble sulphate (SO4 2-) form by soil bacteria (mineralization). Corn growing on deep sandy soils with low organic matter and little clay in the subsoil will likely respond to applications of 10 to 20 kg/ha (9 to 18 lb/ac) SO4-S with pre-plant fertilizers, or with the first N side dressing. If elemental S is used, it may be necessary to apply more than 50 kg/ha (45 lb/ac) in autumn so that at least 10 to 20 kg/ha (9 to 18 lb/ac) of SO4-S is available by early spring.

Calcium (Ca)

Calcium activates growth-regulating enzyme systems, and is needed for cell wall formation and cell division. It improves the root absorption and translocation of other nutrients, and contributes to improved disease resistance. Calcium is taken up by plants as the divalent cation, Ca2+. Along with Mg and K, Ca helps to balance organic acids, which form during cell metabolism.

Symptoms of Ca deficiency are seen in the new growth because Ca is not readily translocated. The symptoms include slowed root development and slowed new leaf growth, with leaf tips sticking together. Calcium deficiency is not likely to occur when the soil is properly limed (See Liming for Optimum Corn Production section). In acidic soils, crop growth is restricted more by toxic concentrations of aluminum and manganese rather than a Ca shortage. Deficiencies are most commonly observed in acid, sandy soils where Ca has been leached by rain or irrigation water, or in strongly acid peat and muck soils with very low soil Ca content.

Magnesium (Mg)

Magnesium, as the central atom in the chlorophyll molecule, is needed for photosynthesis. It is also required for cell division, protein formation, P metabolism, plant respiration, and the activation of several enzyme systems. Magnesium is taken up by the plant as the divalent cation, Mg2+. It is mobile and easily translocated from older to younger tissues.

When deficiencies occur, the older leaves are affected first with a loss of color between the leaf veins, beginning at the leaf margins or tips and progressing inward. Leaves appear striped, with yellowing and browning of leaf tips and edges as symptoms progress (which may be confused with K deficiency), resulting in less photosynthesis and overall crop stunting. Small amounts of Mg can be applied to growing crops through foliar fertilization to correct or prevent developing deficiencies, but the preferred approach is to soil-apply the required amounts before planting.

Plant S, Ca and Mg diagnosis

The best way to diagnose S, Ca and Mg deficiencies is with plant tissue analysis, using specific tissues at different growth stages (Table 5). In the case of S, ratios of total N to total S range from 7:1 to 15:1. Wider ratios may point to possible S deficiency, but should be considered along with actual S and N concentrations in making diagnostic interpretations.

|

Table 5. Sufficient concentrations of S, Ca and Mg in corn tissues |

|||

|

Tissue Selected |

S (%) |

Ca (%) |

Mg (%) |

|

Whole plants less than 12 inches tall |

0.15-0.50 |

0.30-0.70 |

0.15-0.45 |

|

Leaf below the whorl prior to tasseling |

0.15-0.50 |

0.25-0.50 |

0.13-0.30 |

|

Ear leaf at initial silking |

0.21-0.50 |

0.21-1.00 |

0.20-1.00 |

Micronutrients

The function of any nutrient is the origin of the symptom of its deficiency. A listing of the specific functions of each micronutrient (Table 6) helps to illustrate why the detection of a deficiency in corn is often difficult. For example, Fe, Mn and Cu are each involved with chlorophyll formation and a shortage will likely trigger a visible yellowing of plant tissue. Zinc, B, and Mo are each involved with protein formation, which is less likely to trigger a visible symptom, although leaves of zinc deficient plants tend to have yellowish interveinal striping.

|

Table 6. The functions of micronutrients in plant development |

|||||||

|

Plant Growth Function |

Cl |

Fe |

Mn |

Zn |

Cu |

B |

Mo |

|

enzyme systems |

|

X |

X |

X |

X |

|

X |

|

protein formation |

|

X |

|

X |

X |

X |

X |

|

hormones and cell division |

|

|

|

X |

|

X |

|

|

chlorophyll formation |

|

X |

X |

|

X |

|

|

|

disease resistance |

X |

|

|

|

|

|

|

|

photosynthesis |

X |

X |

X |

|

|

|

|

|

N, Fe and/or P metabolism |

|

X |

X |

X |

X |

X |

X |

|

crop maturity |

X |

|

|

|

|

|

|

|

seed formation |

|

|

|

X |

X |

X |

|

|

sugar/starch translocation |

X |

|

|

X |

|

X |

|

Midwest U.S. researchers report that the sensitivity of corn to micronutrient deficiency is low for B and Mo, medium for Cu, Fe and Mn and high for Zn. Liming a strongly acidic soil to a pH level of about 6.0 to 6.5 impacts the availability of all micronutrients except Cl; Fe, Zn, Cu, B and Mn become less available to corn while Mo availability actually increases. Soils high in organic matter are often in need of Cu and B. Alkaline soils, that are also high in P, tend to be responsive to applied Zn. Sandy soils are more likely to be in need of micronutrients than soils high in clay content. Cold, wet soils often trigger Zn deficiency in young corn plants. Land leveling or removal of higher organic matter surface soils also triggers a shortage of Zn. Dry soils late in the season can lead to inadequate B absorption by corn roots.

The total concentration of a micronutrient in the soil is usually a poor indicator of its availability to the corn plant. For example, considerable Fe and Mn might exist in a soil, yet be limiting to plant growth because the nutrients are in a form unsuitable for absorption by roots. The content of B, Zn, Cu or Cl in soils might range from a few to several hundred kg/ha (lb/ac) and adversely affect plant growth as either a deficiency or toxicity. Thus, micronutrient management for high yield corn production should include consideration of the conditions regulating their availability—soil acidity, soil temperature and moisture, genetics, and interactions with other inputs.

Excess concentrations of micronutrients in plants can also be of concern for corn growers. The boundaries for deficiency and excess are close for B, Cu and Zn. Excess levels of Fe and Mn are alleviated by liming acid soils. Excess levels of B, Zn or Cu are seldom a problem in corn production. Occasionally, an excess of Cu or Mn will inhibit Fe metabolism and vice versa.

C.G. KOWALENKO

Agriculture and Agri-Food Canada, Agassiz, British Columbia

The amounts of nutrients that soils contribute to growing crops vary considerably, and amendments such as fertilizer or manure are usually required to obtain high yields. Soil testing is the best currently available option to predict how much and what types of nutrients need to be supplied for a specific field. Although soil test values imply a great degree of reliability, many factors influence their effectiveness for predicting nutrient application requirements. Nutrients are stored in the soil in a variety of complex organic and inorganic forms differing in availability to the crop. Soil tests involve extraction of soil samples with a chemical solution followed by a quantification of nutrients in the solution. The chemical extraction is expected to reflect the amount of nutrient that would be available to the crop. In fact, these extractions have limited ability to simulate plant available nutrients for soils of widely different characteristics and the test that is selected is a compromise for a wide range of soil, weather and crop combinations. Soil tests are based on statistical correlations rather than a defined biological relationship.

General Issues

There are three steps to effective soil testing: sampling and sample preparation, analysis of the sample, and interpretation of the analysis results.

Sampling and sample preparation

When to sample: Time of sampling depends on how the test will be used; for predicting how much nutrient should be added prior to planting, for evaluating the agronomic and environmental performance of nutrient management practices, or for diagnosing a specific crop nutrient problem.

Sampling just prior to planting is recommended for predicting how much fertilizer is required. Sufficient time must be allowed for completing the soil test and for purchasing the recommended fertilizer. Sampling earlier, such as the previous autumn, must be limited to those situations where the nutrient does not change after testing and before applying the nutrients. For example, in south coastal British Columbia where winters are wet and mild, most nutrients measured by soil tests will change over the winter, so sampling close to planting is best (1).

Post-harvest soil sampling is useful for assessing the amounts of available nutrients that were not used by the crop, which is helpful for both agronomic and environmental purposes. This information can be used to adjust management practices (feed-back information) or to monitor long-term trends of nutrients in fields.

Sampling for diagnosing specific nutrient problems is best done when the problem is first observed.

Where to sample: Natural variability of soil test values may be up to 30% in fields that appear uniform (1). Land leveling, banding fertilizers or uneven manure and differential tillage further contribute to variability. To obtain a sample that represents the average nutrient supply in a field or portion of a field, samples from numerous (15 or more) locations should be taken and blended into one sample. Fields where nutrients have been banded require even more samples (2). Unrepresentative areas that can skew results should be avoided or sampled separately.

With the recent advent of yield monitors on harvesting equipment, geographic positioning systems and variable-rate fertilizer applicators, grid sampling of fields with chemical analyses on each sample is becoming more popular (precision agriculture).

How to sample: Depth of sampling depends on mobility of the nutrient and purpose of the test. One approach is to sample to the depth of the majority of root exploration, which in most cases would be the top 15-30 cm (6-12 in). Alternatively, soils are sampled to the depth of cultivation because the soil is mixed and more uniform and most roots are in this zone. Deeper sampling may be required for mobile nutrients with successive depth samples kept separate for analyses and interpretation.

The individual samples from the field that are combined into one to represent the entire field should be the same size, as the samples obtained with using coring devices, to avoid over-representing a specific location. This will minimize bias from any of the sampling locations.

Sample handling: It is important to handle and prepare the sample properly and to avoid contamination, especially with fertilizer or manure. All containers should be clean and of inert material, especially for micronutrient testing. For example, certain paper products contain a lot of boron. Aerial contamination, such as ammonia emitted from manure, must be avoided. Microbial activity should be stopped or minimized after sampling by cooling or drying. Freezing and thawing samples alters some nutrients (3), so refrigeration is preferred for short storage. Nutrients are quite stable in air-dried soil, but drying should be done quickly and at temperatures close to ambient to avoid chemical changes. Air dried samples are easy to mix, use in the laboratory, and store for long periods.

Sample analysis

The methods used to extract and quantify nutrients are usually selected by laboratories. Some general issues related to sample analysis are given below. Details are discussed in a subsequent section.

Extraction of the nutrient from the soil: Extraction involves shaking a sample of soil in a chemical solution. Chemical solutions specific for each nutrient is ideal, but multiple element extracting solutions are popular as this increases efficiency for the laboratory. Multiple element extracting solutions employ a mixture of chemicals, which involves compromises for different soils and nutrients. Also, the soil to chemical solution ratio, and time and vigor of the shaking can influence the amount of nutrient extracted from the soil. Some laboratories scoop a volume of the soil sample for the extraction, while others weigh the sample. This should be considered for interpreting the results or when comparing values for samples analyzed in different laboratories. Some of the filter papers used for extraction contain significant quantities of the elements to be analyzed so they should be washed prior to filtering the sample (4).

Nutrient quantification: The choice of chemical analysis procedures includes consideration of operational factors in the laboratory (e.g., cost of the instrument and its operation, single or multiple analyses) and analytical factors (e.g., sensitivity, freedom from interferences). The type of analysis can have a significant influence on the result. For example, some instruments will measure the total amount of the nutrient including organic or inorganic forms, while others will measure only the inorganic forms. Even laboratories that use the same quantification method produce different results. For example, a recent comparison of 9 laboratories in the US, involving 24 soil samples from 9 states using colorimetry, reported variation from the mean of 10% for Mehlich-III, 13% for Bray-I and 22% for Olsen phosphorus tests (5).

Interpretation

Philosophy: Interpretations of soil tests for fertilizer recommendations vary because of the method used to develop the test (soil test correlation and calibration) and the philosophy for nutrient management (6). In some cases, the goal is to apply sufficient nutrients for optimum yield (referred to as the “sufficiency” approach). In other cases, the goal is to apply sufficient nutrients for the crop and to maintain a specific nutrient content in the soil (“maintenance” approach) or to enhance soil nutrient status (“build-up” approach). The sufficiency approach emphasizes short-term crop production with modest application rates whereas the maintenance and buildup approaches emphasize long-term productivity of the field with greater rates recommended. Soil testing can also be used to monitor long-term trends, but special precautions (e.g., uniform depth and locations of sampling, and method of analysis) are needed.

Units of measurement: Most laboratories use metric units, such as µg/g (µg g-1) or mg/kg (mg kg-1), for expressing their extraction values. Both units are equivalent to ‘parts per million’ or ‘ppm by weight’. These values are often translated into a field unit such a pounds per acre (lb/ac or lb ac-1) or kilograms per hectare (kg/ha or kg ha-1). These units refer to the amount of nutrient in a volume of soil, such as an acre of soil to a depth of six inches or a hectare of soil to a depth of 15 centimeters. To make this conversion, the bulk density (weight of soil in a specified volume) must be used but since these values are not usually measured, an “average” bulk density value is assumed (for mineral soils: ppm in 15 cm or 6 in of soil x 2 = kg/ha or lb/ac). This assumes that a six-inch deep acre of soil weighs two million pounds (15 cm deep ha of soil weighs about two million kg). Organic soils have densities that are less that 1 and should be given special consideration.

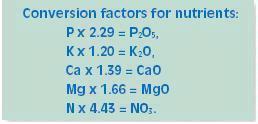

There is often confusion about different units used for the expression of the elements. Most laboratories express the soil sample nutrient measurement on the basis of the element itself (i.e., N, P, K, etc.). However, the units for fertilizers are expressed as %N-%P2O5-%K2O, and recommendations for fertilizer applications are often expressed in these units. Calcium and magnesium tend to be expressed on an element basis (Ca and Mg), but are also sometimes expressed as oxides (CaO and MgO). Clearly, units become more confusing for recommending manure applications.

Although nitrogen is usually expressed as N both for the laboratory analyses and for fertilizers, sometimes this element is expressed as nitrate (NO3). Most nitrogen soil test analyses used today analyze nitrate and express the value as N or NO3 -N but this may not be true of nitrates in feed or drinking water. Care should be taken regarding units of measurement.

Issues Regarding Analysis Methods

Nitrogen (N)

Nitrogen is present in the soil in a variety of forms that change from one to another (see the Nitrogen Cycle section). This has caused the limited use of soil N analyses throughout the world. Most of the N present in agricultural soils is in organic forms yet plants largely feed on inorganic N, particularly nitrate. Nitrate can be readily measured in soils, but the amount in the soil at any one time may not indicate how much is available to plants through the growing season because substantial amounts of inorganic N can be released from the organic forms (a process called mineralization). Unfortunately, the rate of release of inorganic N from the organic matter in the soil cannot be predicted by a chemical analysis at this time. Therefore, N recommendations based on nitrate analyses must take potential mineralization of organic N and losses of nitrate by leaching or as gas into consideration.

Since corn is a long season crop (see The Parable of Fast and Slow Growing Crops section), N can be successfully applied after the crop has been established. A soil test has been developed for guiding sidedress N applications after the crop is established (See Spring Nitrogen Tests section).

Post-harvest soil nitrate analyses can be used to evaluate the agronomic and environmental effectiveness of previous N management (report card) and to adjust N applications for the next season’s crop using feedback information (1) (see Post-Harvest Nitrate Test section).

Phosphorus (P)

Although most soils contain significant proportions of organic P, soil test extractions focus on inorganic P. Solution P, which is extracted by water or a weak solution of calcium chloride, is usually present in low concentrations in soils. The reason is that P is readily adsorbed or precipitated by calcium, magnesium, iron and aluminum compounds and organic matter. These forms are only sparingly soluble. Each contributes different proportions of P to plants, and soil extraction attempts to simulate plant uptake. The correlation between soil P in different extracting solutions and plant growth is affected by soil and weather conditions, hence regions use different extracting solutions (5).

The chemical compositions of some commonly used P extractants are shown in Table 1. The Bray-I extractant was originally developed specifically for P. The Mehlich and Kelowna extraction solutions, developed for multiple nutrient extractions, use some of the same chemicals present in the Bray-I solution.

|

Table 1. Composition of frequently used extraction solutions for soil test P ldeterminations. |

|

|

Extractant |

Composition * |

|

Bray-I |

0.03 M NH4F + 0.025 M HCl |

|

Olsen |

0.5 NaHCOc (pH 8.5) |

|

Mehlich-III |

0.015 N NH4/f + 0.02 M HOAc + 0.25 M NH4NO3 + 0.013M HNO3 + 0.001 M EDTA |

|

Kelowna-I |

0.015 M NH4F + 0.25 M HOAc |

|

Kelowna-II |

0.015 M NH4F + 0.5 M HOAc + 1.0 M NH4OAc |

| * NH4F= ammonium fluoride; HCl = hydrochloric acid; NaHCO3 = sodium bicarbonate; HOAc = acetic acid; NH4NO3 = ammonium nitrate; HNO3 = nitric acid; EDTA = ethylenediamine tetraacetic acid (a chelating chemical largely for micronutrient extraction); NH4OAc = ammonium acetate. | |

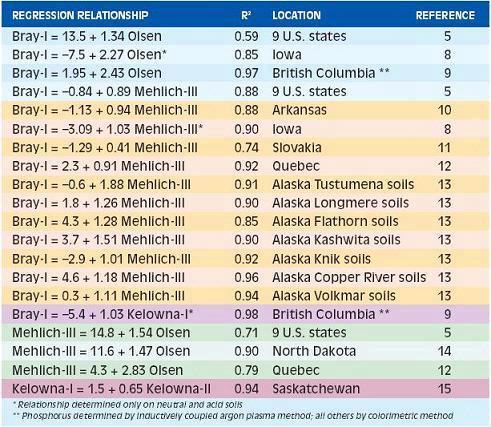

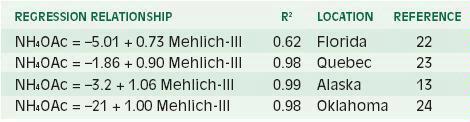

The amount of P extracted by each method is often closely correlated. Some new extractants have been proposed based on correlations with previously used procedures without field correlations and calibrations (7). However, direct comparisons are a challenge. Sometimes laboratories change their methods making historic comparisons difficult. Some relationships between different soil P extractions are shown in Table 2. The regression equations help compare values between methods, however, comparisons should be considered to be region-specific. The Alaska data, which is separated into individual soil series, illustrates the variable relationships that can occur for soil types within a region. Although the overall relationships among the soil test methods are generally quite good (r2 values from 0.74 to 0.91), the actual numerical values may differ with soil type.

Table 2. Comparison of P extract methods at various locations

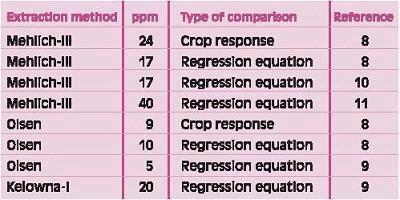

Table 3 compares values derived by either crop response data (8) or by using regression equations for three different extractions equivalent to Bray-I value of 15 ppm. Values were 17-40 for Mehlich-III, 5-10 for Olsen, and 20 for Kelowna-I. This study included crop response data with which the critical value for Mehlich-III and Olsen methods were derived. It is apparent that the regression equations are crude, and using the regression equations derived for the specific region is preferable. Recent research emphasized that actual field calibration data for each method should be used for interpretations even when two methods are closely correlated (16).

Table 3. Comparison of critical values for different extraction solutions with critical value of 15 for Bray-I extraction (derived in an Iowa study (8) determined by crop response data and by calculation using regression equations relating the different extracts).

Analytical instruments also affect P measurements. Colorimeters and ion chromatographs measure inorganic P whereas inductively coupled argon plasma spectrophotometers (ICAP) measure both organic and inorganic P. Various studies have shown that these methods of analysis will result in different P values in the same soil extracts (16, 17, 18, 19, 20, 21). Colorimetric values tend to be slightly greater than ion chromatography values, probably because the strong acids used for colorimetric methods decompose some organic forms of P. Therefore, some of the differences among methods in Table 2 may be due to the quantification method. Studies to develop a new multiple element extraction used the ICAP method for Bray-I and Kelowna-I, but colorimetric analysis for the Olsen extraction method (9). In a study of 10 Quebec soils extracted by Mehlich-III solution, P measured by colorimeter was slightly less than by ICAP (66 vs 72 ppm) but the two methods were highly correlated (12).

Potassium (K)

Some soil K is a structural component of clay minerals or “fixed” in structural voids of certain clay types. Plant available (exchangeable) K is adsorbed to negative charges on the surface of clay minerals, sesquioxides (amorphous iron and aluminum materials) and organic matter. A small amount of K is in the soil solution, which is in equilibrium with the exchangeable fraction.

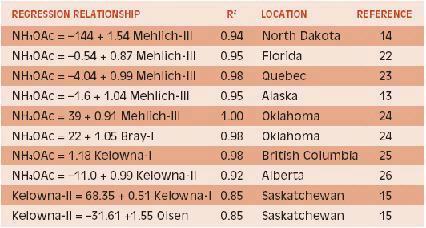

Exchangeable K is typically extracted by ammonium acetate and measured by atomic emission or absorption spectroscopy. Ammonium is particularly effective in displacing K from exchange sites because both atoms are similar in charge and hydrated size. For multiple nutrient analysis with one procedure, ICAP spectrometry is usually coupled with sodium bicarbonate, Mehlich and Kelowna extractions. Results with sodium bicarbonate are somewhat different but correlated to those with ammonium acetate because most soil K is in inorganic form, unlike P. Regression equations among these extraction solutions are shown in Table 4. The nature of the relationship tends to vary with soil type, thus for calculating equivalents among the values it is best to use local data.

Table 4. Comparison of K extracted from soils by different soil test methods.

Magnesium (Mg)

Magnesium, like K, is largely associated with the mineral portion of the soil, and the exchangeable fraction is traditionally extracted with ammonium acetate. However, much less is known about soil test methods for Mg compared to K (27). It is usually assumed that exchangeable Mg is readily available to plants so that ammonium acetate is a suitable soil extractant. The relationship of ammonium acetate with the Mehlich-III extractant is quite good (Table 5).

Table 5. Comparison of Mg extracted from soils by different soil test methods.

Sulphur (S)

Sulphur is often considered to be a “secondary” plant nutrient, required in smaller quantities than N and K but larger quantities than micronutrients such as boron or zinc. Since crop requirements for S are low and variable across regions, relatively little work has been done to develop soil tests. In some locations, sufficient quantities of S are deposited on the soil from the atmosphere (where it is a pollutant) to supply what the crops require but improvements in air quality have reduced this source of S to crops. Sulphur is a coincidental component of some fertilizers. It is chemically bound as potassium sulphate (0-0-50-18S), ammonium phosphate sulphate (16-20-0-15S) and sulphate of potash-magnesia or ‘sulpomag’ (0-0-22-22S). Sulphur is also a contaminant of superphosphate (0-18-0-12S) and triple superphosphate (0-45-0-1S) (28). As fertilizer manufacturers have reduced contaminant S, the requirement for intentional applications of S as fertilizer has increased.

Sulphur is present in the soil in both organic and inorganic forms, with organic S predominant in most soils. Organic S is unavailable to plants unless it is mineralized to inorganic oxidized sulphate (SO4 2-) form. Acidic soils (pH 7), extract S with water or a weak solution of calcium chloride which will not extract adsorbed sulphate in acidic soils. Phosphate-containing solutions are particularly effective and convenient for extraction of both adsorbed and dissolved sulphate (31). Other anions, such as hydroxide, acetate, carbonate and chloride, also displace sulphate but their displacing ability differs from phosphate.

The availability of adsorbed sulphate to plants is uncertain so other extracting solutions have been proposed. For example, hot KCl is thought to extract both solution and adsorbed inorganic sulphate, and to decompose readily plant-available organic S to inorganic sulphate (32). Unfortunately, the relationships between many proposed extractants are not well known (33, 34, 35). Adoption of multiple nutrient extractants (especially for P, K and Mg) for S testing has been constrained by insufficient field correlation data. A study in India (36) reported the following relationships between Mehlich-III (multiple nutrient extractant) and frequently used S extraction solutions:

Mehlich-III = 13.04 + 6.79 CaCl2, r2 = 0.83,

Mehlich-III = 20.82 + 0.92 Ca-PO4, r2 = 0.80, and

Mehlich-III = 13.89 + 0.73 Morgan’s, r2 = 0.87.

The solutions tested were calcium chloride (CaCl2), monocalcium phosphate (Ca-PO4) and sodium acetate plus acetic acid (Morgan’s), and sulphate was measured by a barium-based turbidimetric method. In British Columbia, the Kelowna-I multiple nutrient extractant was adopted for S soil testing after correlating with calcium chloride extraction using 40 soils from across the province (37). The relationship for the two methods is:

Kelowna-I = 2.61 + 1.79 CaCl2 r2 = 0.61.

Some data has shown that Mehlich-II (ammonium fluoride, acetic acid, ammonium chloride and hydrochloric acid) extraction cannot be generally used for determining “the S supplying” ability of soils (38).

A further complication, as for P, is that different analytical methods will measure different forms of S (31). Turbidimetric/colorimetric and ion chromatographic methods measure inorganic sulphate-S, hydriodic acid reduction method measures both organic and inorganic forms of sulphate-S whereas ICAP will measure all inorganic and organic forms of S. Hence, the turbidimetric/colorimetric methods will result in the smallest value, the hydriodic acid method will have intermediate values and ICAP will result in the largest value, depending on forms extracted from the soil.

Calcium (Ca), pH and lime

Most soils, especially those of alkaline pH, have adequate quantities of Ca for crop growth. Deficiencies may occur in acidic soils, but the application of liming materials to maintain a suitable pH (near neutrality for most crops) is assumed to provide more than adequate amounts of Ca. Since applications of liming materials is standard soil practice in most regions (except where sources are scarce), pH is widely used to indicate liming needs.

There is often confusion in interpretation of buffer and non-buffer pH values (39). Non-buffer pH values, usually a measurement of soil in water or a weak solution of Ca or K, indicates the pH of the soil as experienced by plants. Buffer pH indicates how much liming material needs to be applied to achieve a non-buffer pH value. Laboratories use different buffer solutions for this measurement and each would have a different relationship or equation to derive the lime requirement. A single-buffer method is used quite widely and the equations used to determine tonnes of limestone per hectare (for T/ac multiply by 0.45) for mineral soils that should be applied to achieve a pH of 6.5 are (40):

Quebec lime recommendation = 107.2 – 22.27 pH + 0.983 (pH2), and

Ontario lime recommendation = 291.6 – 80.99 pH + 5.64 (pH2).

While liming recommendations are based on limestone (calcium carbonate or CaCO3), other materials can also be used. The acid-neutralizing capacity of these products, expressed relative to limestone as calcium carbonate equivalent (28) are:

- pure, finely ground limestone 100%

- hydrated lime (calcium hydroxide or Ca(OH)2) 120-130%

- burned or quick lime (calcium oxide or CaO) 150-175%

- dolomite or dolomitic limestone (CaCO3.MgCO3) 110%

Both hydrated and burned/quick lime react quickly in the soil but require careful handling because of their caustic nature. Dolomite materials have relatively high Ca carbonate equivalents and supply Mg but act slowly and are usually more expensive than limestone (see Liming to Increase Cell pH section).

Micronutrients

Nutrients required by crops in very small quantities, such as boron, iron, manganese, copper, zinc, and molybdenum, are called micronutrients. Chloride is referred to as a micronutrient but required in greater quantities than true micronutrients (see Latest on Chloride Fertilizer section). Inadequate amounts of these elements will reduce crop growth and quality, and plants would respond to applications of these as fertilizer. Although soil tests have been proposed for all of these nutrients (41, 42, 43, 44), field trials to support the use of these are quite limited in most locations as is the case for British Columbia (45). These soil tests should be used only when all other nutrient problems have been resolved. Test strips in the field should be used to assess response before micronutrients are applied extensively because of both their cost and possible detrimental effects from excessive applications.

References

1. Kowalenko, C.G. 1991. Fall vs. spring soil sampling for calibrating nutrient applications on individual fields. J. Prod. Agric. 4, 322-329.

2. Zebarth, B.J., M.F. Younie, J.W. Paul, J.W. Hall and G.A. Telford 1999. Fertilizer banding influence on spatial and temporal distribution of soil inorganic nitrogen in a corn field. Soil Sci. Soc. Am. J. 63, 1924-1933.

3. Esala, M.J. 1995. Changes in the extractable ammonium- and nitrate-nitrogen contents of soil samples during freezing and thawing. Commun. Soil Sci. Plant Anal. 26, 61-68.

4. Scharf, P. and M.M. Alley 1988. Centrifugation: a solution to the problem posed by ammonium and nitrate contamination of filters in soil extract analysis. Soil Sci. Soc. Am. J. 52, 1508-1510.

5. Kleinman, P.J.A., A.N. Sharpley, K. Gartley, W.M. Jarrell, S. Kuo, R.G. Menon, R. Myers, K.R. Reddy and E.O. Skogley 2001. Interlaboratory comparison of soil phosphorus extracted by various soil test methods. Commun. Soil Sci. Plant Anal. 32, 2325-2345.

6. Brown, J.R. (ed.) 1987. Soil testing: sampling, correlation, calibration, and interpretation. Special Publication number 21. Soil Sci. Soc. Am., Madison, Wisc.

7. Fixen, P.E. and J.H. Grove 1990. Testing soils for phosphorus. Pages 141-180 IN R.L. Westerman (ed.) Soil testing and plant analysis. Third edition. Book series number 3. Soil Sci. Soc. Am., Madison, Wisc.

8. Mallarino, A.P. 1997. Interpretation of soil phosphorus tests for corn in soils with varying pH and calcium carbonate content. J. Prod. Agric. 10, 163-167.

9. van Lierop, W. 1988. Determination of available phosphorus in acid and calcerous soils with the Kelowna multiple-element extractant. Soil Sci. 146, 284-291.

10. Sabbe, W.E. and S.C. Dunham 1988. Comparison of soil phosphorus extractants as affected by fertilizer phosphorus sources, lime recommendation and time among four Arkansas soils. Commun. Soil Sci. Plant Anal. 29, 1763-1770.

11. Matejovic, I. and A. Durackova 1994. Comparison of Mehlich 1-, 2-, and 3-, calcium chloride-, Bray-, Olsen-, Enger-, and Schachtschabel-extractants for determinations of nutrient in two soil types. Commun. Soil Sci. Plant Anal. 25, 1289-1302.

12. Tran, T.S., M. Giroux, J. Guilbeault and P. Audesse 1990. Evaluation of Mehlich-III extractant to estimate the available P in Quebec soils. Commun. Soil Sci Plant Anal. 21, 1-28.

13. Michaelson, G.J., C.L. Ping and G.A. Mitchell 1987. Correlation of Mehlich 3, Bray 1, and ammonium acetate extractable P, K, Ca, and Mg for Alaska agricultural soils. Commun. Soil Sci. Plant Anal. 18, 1003-1015.

14. Schmisek, M.E., L.J. Cihacek and L.J. Swenson 1998. Relationship between the Mehlich-III soil test extraction procedure and standard soil test methods in North Dakota. Commun. Soil Sci. Plant Anal. 29, 1719-1729.

15. Qian, P., J.J. Schoenaru and R.E. Karmanos 1994. Simultaneous extraction of available phosphorus and K with a new soil test: a modification of Kelowna extraction. Commun. Soil Sci. Plant Anal. 25, 627-635.

16. Mallarino, A.P. 2003. Field calibration for corn of the Melich-3 soil phosphorus test with colorimetric and inductively coupled plasma emission spectroscopy determination methods. Soil Sci. Soc. Am. J. 68, 1928-1934.

17. Bolland, M.D.A. and I.R. Wilson 1994. Comparison of standard and total Colwell procedures for measuring soil test phosphorus. Commun. Soil Sci. Plant Anal. 25, 2395-2407.

18. Hylander, L.D., H.-I. Svensson and G. Simán 1995. Comparison of different methods for determination of phosphorus in calcium chloride extracts for prediction of availability to plants. Commun. Soil Sci. Plant Anal. 26, 913-925.

19. Hylander, L.D., H.-I. Svensson and G. Siman 1996. Different methods for determination of plant available soil phosphorus. Commun. Soil Sci. Plant Anal. 27, 1501-1512.

20. Masson, P., C. Morel, E. Martin, A. Oberson and D. Friesen 2001. Comparison of soluble P in soil water extracts determined by ion chromatography, colorimetric and inductively coupled plasma techniques in ppb range. Commun. Soil Sci. Plant Anal. 32, 2244-2253.

21. McDowell, R.W. and A.N. Sharpley 2001. Soil phosphorus fractions in solution: influence of fertilizer and manure, filtration and method of determination. Chemosphere 45, 737-748.

22. Alva, A.K. 1993. Comparison of Mehlich 3, Mehlich 1, ammonium bicarbonate-DTPA, 1.0M ammonium acetate, 0.2M ammonium chloride for extraction of calcium, magnesium, phosphorus, and potassium for a wide range of soils. Commun. Soil Sci. Plant Anal. 24, 603-612.

23. Tran, T.S. and M. Giroux 1989. Évaluation de la méthode Mehlich-III pour déterminer les éléments nutritifs (P, K, Ca, Mg, Na) des sols du Quebéc. Agrosol 2, 27-33.

24. Hanlon, E.A. and G.V. Johnson 1984. Bray/Kurtz, Mehlich III, AB/D and ammonium acetate extractions of P, K and Mg in four Oklahoma soils. Commun. Soil Sci. Plant Anal. 15, 277-294.

25. van Lierop, W. and N.A. Gough 1989. Extraction of potassium and sodium from acid and calcareous soils with the Kelowna multiple element extractant. Can. J. Soil Sci. 69, 235-242.

26. Ashworth, J. and K. Mrazek 1995. “Modified Kelowna” test for available phosphorus and potassium in soil. Commun. Soil Sci. Plant Anal. 26, 731-739.

27. Habey, V.A., M.P. Russelle and E.O. Skogley 1990. Testing soils for potassium, calcium, and magnesium. Pages 181-227 IN R.L. Westerman (ed.) Soil testing and plant analysis. Third edition. Book series number 3. Soil Sci. Soc. Am., Madison, Wisc.

28. Soil Improvement Committee California Fertilizer Association 1980. Western Fertilizer Handbook. The Interstate Printers and Publishers, Inc., Danville, Ill.

29. Tabatabai, M.A. 1982. Sulfur. Pages 501-538 IN A.L. Page, R.H. Miller and D.R. Keeney (eds.) Methods of soil analysis. Part 2. Chemical and microbiological properties. 2nd ed. Agonomy No. 9. Am. Soc. Agron., Madison, Wisc.

30. Kowalenko, C.G. 1996. Interpretation of autumn soil tests for hazelnuts. Can. J. Soil Sci. 76, 195-202.

31. Kowalenko, C.G. 1993. Extraction of available sulfur. Pages 65-74 IN M.R. Carter (ed.) Soil sampling and methods of analysis. Lewis Publ., Boca Raton.

32. Anderson, G.C., G.J. Blair and R.D.B. Lefroy 1998. Soil-extractable sulfur and pasture response to applied sulfur 2. Seasonal variation in soil sulfur tests and sulfur response by pastures under field conditions. Australian J. Experimental Agric. 38, 575-582.

33. Alewell, C and E. Matzner 1996. Water, NaHCO3-, NaH2PO4- and NaClextractable SO4 2- in acid forest soils. Zeitschrift Für Pflanzenernahrung und Bodenkunde 159, 235-240.

34. Prietzel, J. and C. Hirsch 2000. Ammonium fluoride extraction for determining inorganic sulphur in acid forest soils. European J. Soil Sci. 51, 323-333.

35. Schmalz, V., T. Grischek, G. Gerstäcker and E. Eckard 2001. Comparison of different extractants for the determination of inorganic sulphate in gypsumfree agricultural soils. J. Plant Nutr. Soil Sci. 164, 577-578.

36. Rao, T.N. and P.K. Sharma 1997. Evaluation of Mehlich III as an extractant for available sulphur. Commun. Soil Sci. Plant Anal. 28, 1033-1046.

37. Kowalenko, C.G. 1993. Sulphur. Pages 33-37 IN C.G. Kowalenko (ed.) Soil test analysis methods for British Columbia agricultural crops. Proceedings of a workshop of the British Columbia Soil and Tissue Testing Council, meeting 24 November 1992. B.C. Min. Agric., Fisheries and Food, Victoria.

38. Matula, J. 1999. Use of multinutrient soil tests for sulphur determination. Commun. Soil Sci. Plant Anal. 30, 1733-1746.

39. van Lierop, W. 1990. Soil pH and lime requirement. Pages 73-126 IN R.L. Westerman (ed.) Soil testing and plant analysis. Third edition. Book series number 3, Soil Sci. Soc. Am., Madison, Wisc.

40. Tran, T.S. and W. van Lierop 1993. Lime reqirement. Pages 109-113 IN M.R. Carter (ed.) Soil sampling and methods of analysis. Lewis Publ., Boca Raton, Florida.

41. Liang, J. and R.E. Karmanos 1993. DTPA-extractable Fe, Mn, Cu, and Zn. Pages 87-90 IN M.R. Carter (ed.) Soil sampling and methods of analysis. Lewis Publ., Boca Raton, Florida.

42. Gupta, U.C. 1993. Boron, molybdenum, and selenium. Pages 91-99 IN M.R. Carter (ed.) Soil sampling and methods of analysis. Lewis Publ., Boca Raton, Florida.

43. Martens, D.C. and W.L. Lindsay 1990. Testing soils for copper, iron, manganese, and zinc. Pages 229-264 IN R.L. Westerman (ed.) Soil testing and plant analysis. Third edition. Book series number 3, Soil Sci. Soc. Am., Madison, Wisc.

44. Johnson, G.V. and P.E. Fixen 1990. Testing soils for sulphur, boron, molybdenum, and chlorine. Pages 265-273 IN R.L. Westerman (ed.) Soil testing and plant analysis. Third edition. Book series number 3, Soil Sci. Soc. Am., Madison, Wisc.

45. Kowalenko, C.G. and G.H. Neilsen 1992. Assessment of the need for micronutrient applications for agricultural crop production in British Columbia. Agric. Canada Res. Branch Tech. Bull, 1992-5E.

C.G. KOWALENKO

Agriculture and Agri-Food Canada, Agassiz, BC

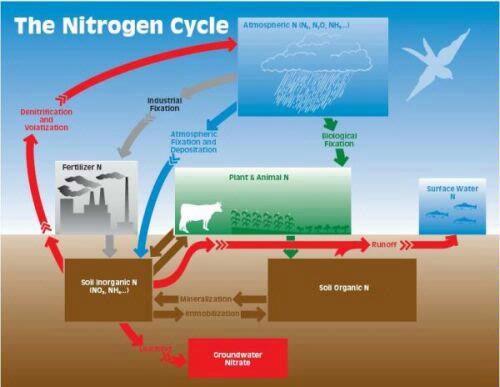

One of the fundamentals of nature is that matter is not spontaneously created or destroyed, but can be changed from one form to another. This is true of nitrogen (N), which cycles through every part of the ecosystem in well known but exceedingly complex flows.

To understand the N cycle, it is best to recognize that N is present in various forms and names have been given to the processes that convert it from one form to another (Fig. 1). The forms that contain the majority of N in nature, N gas (N2 constitutes 80% of the atmosphere) and soil organic N, are not directly available to plants. Inorganic N in the form of ammonium or nitrate is available to plants.

Conversion of N gas to a plant available (inorganic) form is called fixation, and it is accomplished naturally in the atmosphere, biologically and industrially (Fig. 1). Fixation of N gas occurs in the atmosphere during lightning events. Ammonium in the atmosphere can be deposited directly to plants and soil or via precipitation. Biological fixation is carried out by N-fixing bacteria living symbiotically with many species of legumes, by free-living bacteria and by blue-green algae. Fertilizer N is manufactured (fixed) industrially using the very energy demanding Haber-Bosch process invented prior to World War I. This single industrial process provides most of the N fertilizer needed to feed the human population. It should be the goal of every farmer to conserve valuable fixed N.

Organic N accumulates in soil by additions of plant and animal wastes or residues. Conversion of soil organic N to inorganic N is called mineralization whereas the conversion of inorganic N to organic N is called immobilization. The first inorganic N product of mineralization is ammonium. Ammonium is usually converted quickly to nitrate by a process called nitrification, hence, nitrate is the dominant inorganic N form available to plants. Ammonium is lost from the soil to the atmosphere by volatilization and nitrate by denitrification. Nitrate does not adhere to soil particles and, hence, is vulnerable to leaching out of the root zone as water percolates through the soil. Soil organic and inorganic N can be lost to surface water by erosion and run-off.

Nitrogen in the Environment

The biological or non-biological processes that convert N from one form to another respond to climatic, soil and environmental conditions differently. An understanding of the forms and factors that influence conversion is necessary for efficiently managing N on farms.

Although N is an essential nutrient for all plants and animals, it can have detrimental environmental effects on air, water and natural ecosystems. Ammonia, which volatilizes from manures and fertilizer into the atmosphere, has a strong odour. At high concentrations, it can be an irritant or even directly toxic to humans. Ammonia in the atmosphere may be deposited near (1 km or 0.6 mi) the source in significant quantities. Ammonia that is not immediately deposited can combine in the air with nitrate and sulphate from factories and automobiles to form fine particulates which reduce air quality (white haze) and can be detrimental to human health. High levels of fine particulates have been recorded in the confined valleys of the lower Fraser River (BC) and San Joaquin Valley (CA). Atmospheric ammonia deposited on the earth or surface water bodies via precipitation can be toxic to some aquatic organisms, stimulate excessive biological growth in water (eutrophication), accelerate acidification of soils or cause changes to natural aquatic and terrestrial ecosystems that may degrade species diversity. In contrast to ammonia, nitrate is not volatile but contributes to atmospheric contamination during denitrification, which occurs most often in wet soils. The main product of denitrification is innocuous atmospheric N gas (N2), but nitric oxide (NO) and nitrous oxide (N2O), are formed in small quantities as intermediates. These are potent greenhouse gases which contribute to global warming. Small amounts of nitrous oxide are also formed during nitrification.

Nitrogen in the soil during corn production is subject to nutrient loss by leaching, erosion and runoff, particularly before planting and after harvest when there is little cover over the soil. Erosion and runoff (Fig. 1) of N (both organic and inorganic) contribute to eutrophication of surface waters and ammonium in surface water is very toxic to many aquatic organisms such as fish. Nitrate leached from soils into groundwater is a widely recognized environmental and health concern, particularly due to the potential death of infants from “blue baby” syndrome.

B.J. ZEBARTH

Agriculture and Agri-Food Canada, Fredericton, New Brunswick

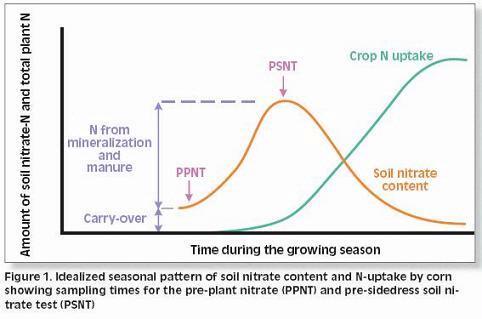

Most of the N in soils is organic and must be converted to nitrate or ammonium (mineralization) before it is available to plants (see The Nitrogen Cycle section); nitrate is the predominant inorganic form in most soils. Nitrate can be high in early spring in some fields as a result of the carry-over from the previous growing season. The amount of carry-over varies with the amount of soil nitrate present in fall and the losses over the fall and winter. In some locations, such as coastal regions of the Pacific Northwest which are mild and wet, carry-over is minimal. In locations where winters are cold and dry, carry-over can be considerable. When the amounts of carry-over nitrate plus mineralized N is less than the crop requires, application of N as fertilizer or manure is required.

The amount of soil inorganic N that will be mineralized during the growing season cannot currently be predicted with a chemical analysis (see Determining Nutrients Available in Soils section), therefore, soil N testing is limited to measuring inorganic N. In south coastal British Columbia, where soil N fertility on dairy farms is high due to a history of manure use, net soil N mineralization is commonly greater than 100 kg N/ha, with some fields exceeding 200 kg N/ha. In locations where carry-over nitrate is leached below the root zone over winter, a pre-plant test has limited value for determining fertilizer requirements. Since corn is a long-season crop (see Parable of the Fast and Slow Growing Crops section), soil nitrate testing can be delayed to just prior to sidedress fertilizer time in order to detect as much soil nitrate as possible from mineralization and nitrification.

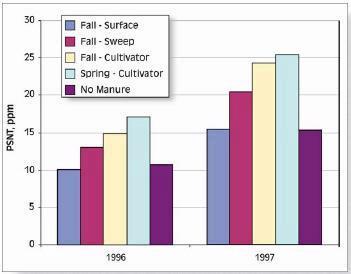

Two Soil N Tests: PPNT and PSNT

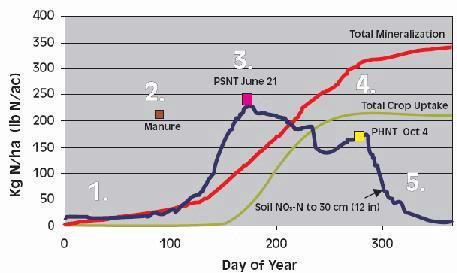

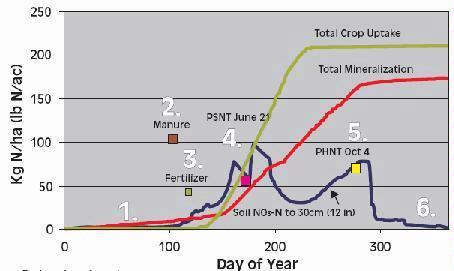

The two most common soil N tests used for determining nitrogen available for corn are the pre-plant soil nitrate test (PPNT) and the pre-sidedress soil nitrate test (PSNT). The PPNT is based on the soil nitrate concentration to 60-cm depth measured before planting (Fig.1). This test measures mainly the amount of soil nitrate carried over from the previous growing season plus early-season soil N mineralization. This test works best in dry or cold climates where carry-over of nitrate from the previous year contributes a major proportion of the total soil N supply. Disadvantages of the PPNT are that the sample is taken prior to most growing season mineralization and nitrification of soil organic matter and spring applied manure N. The PPNT might be improved in some fields by including a measure of soil ammonium concentration.

The PSNT is based on the soil nitrate concentration to 30-cm depth measured at the six-leaf stage, just prior to the period of rapid crop N uptake (Fig. 1). The PSNT works best when no more than 20-30 kg N/ha (18-27 lb/ac) is banded at planting. Based on studies in coastal British Columbia, soil nitrate measured at this time includes little carry-over from the previous growing season, about 50% of the soil N mineralization which will occur throughout the growing season, and most of the available N from spring-applied liquid dairy manure (1). Usually, most nitrification of soil and manure ammonium is complete by the time the PSNT sample is taken, so measurement of soil ammonium is not required. However, where corn was planted after plough-down of forage grass in early May (i.e. after first cut), more than half of the plant available N in the soil was still in ammonium form when the PSNT sample was taken.

Thanks to the delayed sampling, the PSNT is more sensitive to soil N ineralization and spring manure application than the PPNT, and, except where carry-over is substantial, should provide better estimates of fertilizer N requirement than the PPNT. In cases where carry-over N is significant, it may be helpful to use the PPNT to choose an appropriate spring manure application rate, and to use the PSNT to choose an appropriate sidedress fertilizer N rate.

How to use pre-sidedress soil nitrate tests (PSNT)

It should be part of a nitrogen management system:

- Manage manure according to local environmental guidelines; in some years, liquid manure alone may supply enough N for your crop.

- Do not broadcast N before planting. Corn requires little N early in the growing season.

- Apply a low rate of N (20-30 kg/ha or lb/ac) with the planter. Nitrogen applied by the planter is not measured by the PSNT.

- Use the PSNT to decide how much, if any, fertilizer N to apply at sidedress.

Sampling protocol:

- Sample to 30-cm (1-ft) depth midway between corn rows to avoid fertilizer banded with the planter.

- Take at least 10 cores per field when the corn is at the 6-leaf stage or 15-30 cm (6 – 12″) tall.

- Keep the sample cool or frozen until it reaches the lab — a picnic cooler is handy; warm samples will release nitrate and give a fertilizer recommendation which is too low.

- Have the sample analysed for nitrate-N concentration in ppm.

Interpreting results:

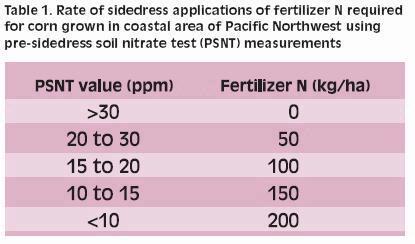

- Corn will likely not respond to sidedress N in fields with PSNT values greater than the critical PSNT value. Critical PSNT values vary somewhat with region so use local information. The most common critical PSNT values in North America are 20-25 ppm.

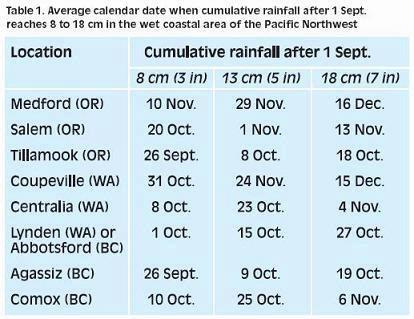

- For PSNT test values less than the critical PSNT value, use local information to predict the fertilizer N requirement at sidedress. Table 1 shows values for coastal Pacific Northwest (1).

- Field measurements have shown that where corn was planted following a late-spring plough-down of forage grass, more than half of the plant available nitrogen in the soil was still in ammonium form when the PSNT sample was taken. In this case, PSNT will over-predict N needs.

Future technology: plant chlorophyll N tests