B.L. MA, D.W. STEWART, AND L.M. DWYER

Agriculture and Agri-Food Canada, Ottawa, Ontario

Corn Maturity and Corn Heat Units

Corn is a tropical grass and even though it has been grown in temperate regions for hundreds of years by native people, it is still more sensitive to temperature than cool season crops like small grain cereals and alfalfa. Although day-length and soil factors (moisture, nutrients) have an influence, the development of corn from emergence, through tasselling, silking, and grain filling, to physiological maturity follows closely the amount of accumulated heat. Therefore, time to maturity will depend on the date of seeding, weather during the growing season and the corn hybrid. Since the temperature during the growing season is the most important factor, it can be used to predict maturity dates of different hybrids. This is useful for both the corn breeder and the farmer.

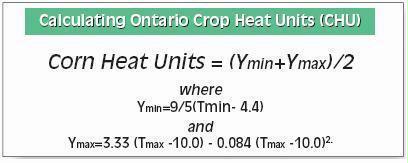

The most common calculation for accumulated heat for corn in Canada is the ‘Ontario Crop Heat Unit’ (CHU). This calculation is based on the maximum (Tmax) and minimum (Tmin) daily temperature in degrees Celsius. This index reflects that growth rate of corn:

- increases proportionately to minimum daily temperature (usually night-time temperature), at all temperatures above 4.4°C (40°F)

- increases at increasing rates with maximum daily temperature (usually daytime temperature) from 10 to 30°C (50 to 86°F), then at decreasing rates to 50°C (122°F).

A hybrid rated at 3,000 CHU’s will require that many heat units from planting to formation of black layer. The black layer is a thin black line that forms at the base of each kernel at maturity. We will discuss maturity in more detail below.

In the United States, a Growing Degree Day (GDD) index is used to describe maturity of corn hybrids. It is expressed as:

GDD= ( Tmax+Tmin )/ 2 -10.0

In this system, Tmax values above 30°C (86°F) are set to 30°C while Tmax or Tmin below 10°C (50°F) are set to 10°C. Growing Degree Day units are summed from planting to maturity.

Because different assumptions are made for the two indices, they cannot be directly equated. As an approximation, 3,000 CHU’s corresponds to about 1,265 GDD units.

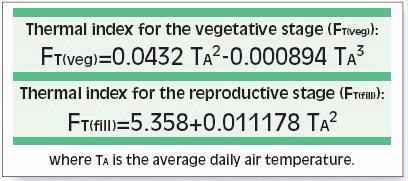

Recently a new index, called the General Thermal Index, was developed for corn hybrids in northern United States and Canada. The general thermal index was designed to be approximately equal to growing degree days. This index combines separate calculations for vegetative (before silking) and reproductive (after silking) stages of corn growth. Instead of the actual date of silking, a transition date of Aug. 1 can be used.

The equation for the vegetative phase represents a typical biological response curve that starts at 0°C (32°F), rises to a maximum near 30°C (86°F) and then declines. However, the reproductive index has substantial value at 0°C (32°F) and rises almost linearly as temperature increases. It fits the common observation that corn continues to mature even when temperatures fall to near zero. Poorly understood factors other than temperature are at work here. The General Thermal Index is more consistent than other indices, but is far from perfect.

Estimating Maturity and Silage Moisture at Harvest

Cutting at the right stage of maturity has a large effect on both the quality and quantity of corn silage. The heat unit system cannot yet predict moisture content of the crop because of the influence of hybrid, population density and weather, particularly rainfall. So the question still remains: when should corn silage be harvested? The best time is when whole-plant moisture content is between 62 and 70%. But when does this happen? Certainly before black layer formation.

Kernels reach their final size within two weeks after silking, then begin to fill. During the filling period, as dry matter accumulates and moisture drops, a white line appears near the top of the kernels (100% milk-line) (Fig. 1). As the crop matures, the line recedes to the base of the kernels (0% milk-line). When milk-line reaches zero, under normal conditions, a black line or layer appears at the base of the kernels signaling physiological maturity. However, the black layer can appear before 0% milk-line when grain filling is hampered by early fall frost. As this is happening, most hybrids have kernels that will dent at the top surfaces. While the most visible indicator of maturity is black layer formation, the most important maturity factor for both grain and silage is moisture content. Unfortunately, moisture content is not easily estimated by eye and for best accuracy must be measured directly.

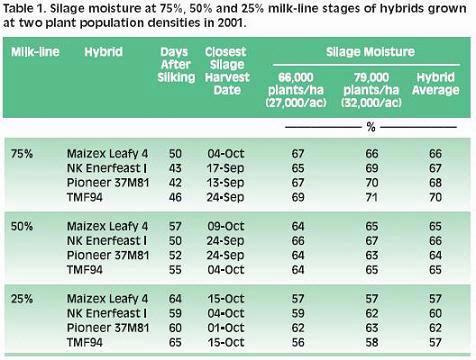

In eastern Ontario, 50% milk-line in dualpurpose corn hybrids broadly indicates that 65% whole-plant moisture and over 85% of maximum yield has been reached— a good indicator for silage harvest. However, the relationship between kernel milk-line and plant moisture content varies with hybrid and weather conditions. For example, after the relatively cool summer of the year 2000, the 65% plant moisture level in four hybrids corresponded to kernel milk-lines ranging from 90 to 26%. In 2001, 75% milkline stage indicated 66 to 70% silage moisture and 50% milk-line indicated approximately 65% moisture. At 25% milk-line, silage moisture ranged from 57% for hybrids Maizex Leafy 4 and TMF94 to 62% for Pioneer 37M81 (Table 1). In all cases, large variations existed for % milk-line within plots and among replications. In an earlier study on grain corn, 50% milk-line ranged from 39% kernel moisture contents in 1995, a warm year, to 42% moisture in 1996, a relatively cool year. Furthermore, it is often difficult to determine the milk-line stages for Leafy hybrids (Fig. 1). As plant moisture was determined on a whole-plant basis (5-10 plants), variability in silage moisture was much smaller among replications and population densities (Table 1), highlighting the importance of determining harvesting time based on the actual silage moisture. There fore, a decision on silage harvest time should be based on the actual measurement of silage moisture (see Timing Harvest section).

Similarly, in Ohio, it was also found that kernel milk-line was a less reliable method for determining time for silage harvest (see next section).

Figure 1. Kernel milk-line stages from full dent (100% ML) to 0% ML (black layer) in a leafy hybrid. Note within an ear, kernel stages varied from full dent to 75% ML, sometimes black layer occurred at 25%ML, and the milk line stage is recorded on average kernels, which is evaluated when removed from the cob.

Table 1. Silage moisture at 75%, 50% and 25% milk-line stages of hybrids grown at two plant population densities in 2001

Window for Silage Harvest

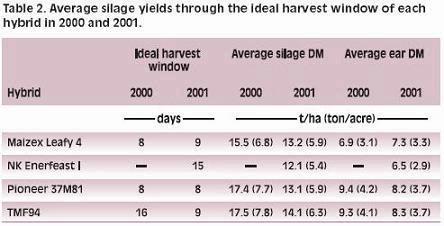

Silage varieties should be harvested at maximum whole-plant dry matter yield with the ideal moisture at 62 to 70%. Unlike grain corn, silage hybrids should have the characteristics of slow maturing, soft starch kernels, slow dry down of stalks and low concentration of neutral detergent fibre (NDF) with high NDF digestibility. Recent studies indicate that hybrids with the “leafy” trait (having additional leaves above the ear) dry down more slowly than non-leafy types. For example, under cool conditions of the year 2000, leafy hybrid TMF94 had a harvest window of approximately 16 days, double that of Maizex Leafy 4 and Pioneer 37M81 (Table 2). In 2001, the whole-plant moisture of the dual-purpose hybrid Pioneer 37M81 dropped more quickly than the leafy hybrids. Based on the goal of 90% of maximum dry matter yield within the ideal moisture range for silage, harvest windows in 2001 were 8 days for Pioneer 37M81, 9 days for TMF94 and Maizex Leafy 4 and 15 days for NK Enerfeast I (Table 2). Harvest windows for both Maizex Leafy 4 and Pioneer 37M81 were similar under contrasting weather but the harvest window for TMF94 was weather-sensitive.

Table 2. Average silage yields through the ideal harvest window of each hybrid in 2000 and 2001.

Kernel Hardness

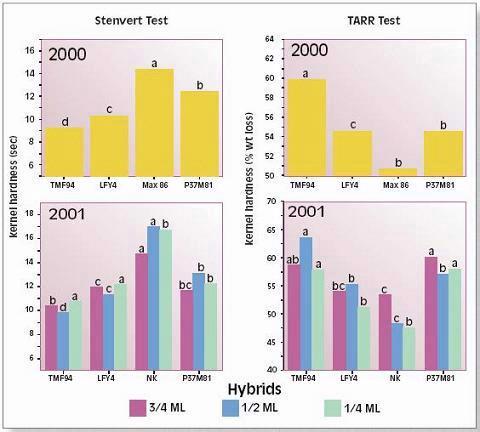

Kernel hardness has been found to be an indicator of silage digestibility. Kernel hardness is currently determined using two types of measurement: Stenvert and TARR. The Stenvert procedure involves passing a 20 g sample of air-dried kernels through a hammer mill and determining the time it takes to fill a certain volume. The TARR test measures the % weight loss of an air-dried kernel sample through a vibration machine. The less time required in the Stenvert procedure or the greater amount of weight loss in the TARR test, the softer is the kernel. Although affected by stage of maturity, kernels of leafy hybrids are consistently softer than those of dual-purpose hybrids (Fig. 2). Kernels make up 40-50% of total plant dry matter. The softer kernels in leafy hybrids indicate that under the same ensiling conditions, there will be more digestible energy produced by leafy hybrids than non-leafy dual-purpose hybrids.

Figure 2. Kernel hardness test results using a Stenvert or TARR in 2000 (0 milk-line) and 2001. Within a harvest time, bars with different letters are statistically different.

Summary

Corn development is governed by heat, which can be expressed as Growing Degree Days, Crop Heat Units or a Generalized Thermal Index. The indices are helpful in selecting silage varieties and anticipating the proper stage for silage harvest. Silage moisture content determines the window for harvest. Silage cannot be harvested close to physiological maturity when maximum dry matter is reached. Rather, silage should be harvested at around 65% whole-plant moisture content, which normally corresponds to 50% kernel milk stage. However, the relationship between kernel milk-line and silage moisture content is affected by growing conditions, especially rainfall; whole-plant moisture at 50% kernel milk-line, used for timing silage harvest, also varies with hybrid. Compared to dual-purpose hybrids, leafy silage hybrids have soft kernels and slow decline in whole-plant moisture content so they provide producers with a larger window for harvest.

R.M. SULC

The Ohio State University, Columbus, Ohio

Determining the proper time to harvest corn for silage is critical because it influences the overall quality of the product that is preserved and stored in the silo. As described in the chapter “Making Good Corn Silage”, the moisture content critically affects silage fermentation and preservation. Harvesting corn too wet (low DM content) results in souring and seepage of the silage and reduction in animal intake. Harvesting too dry (high DM content) promotes mould development because the silage cannot be adequately packed to exclude oxygen. Harvesting too dry also results in lower digestibility, protein, and vitamins A and E. So harvesting corn at the proper dry matter content will result in better animal performance and lower feed costs.

Harvest Moisture Guidelines

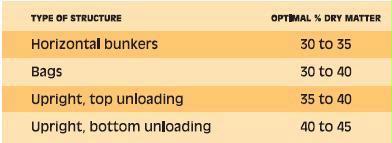

Corn silage preserved between 30 and 40% DM (60 to 70% moisture) generally provides good silage fermentation and animal performance. The optimal DM content varies with type of storage structure (Table 1).

Table 1. Optimal dry matter contents for different storage structures.

Determining Silage Moisture

Predicting when to harvest corn to achieve the proper % DM for ensiling is difficult because there is no easily identifiable plant trait that can be used to reliably and accurately estimate the whole-plant % DM. The only reliable method of determining the optimal time to harvest corn silage is to sample the crop and directly measure the % DM of whole plants. The following procedures were developed for sampling fields and measuring moisture content to plan harvest dates. The whole-plant % DM information combined with average whole-plant drydown rates can be used to roughly predict the proper time to harvest silage.

When to Begin Field Sampling

Sampling fields to measure whole-plant dry matter content should be done well before the anticipated harvest date in case corn is drying down faster than expected. Silking date can be used as a rough indicator of which fields are likely to be the earliest to harvest. The dent stage occurs about 35 to 42 days after silking, which is when fields should first be checked for kernel milk stage development.

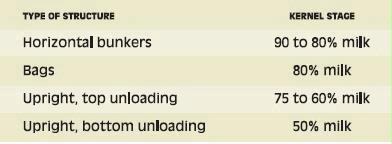

While kernel milk stage cannot be relied upon to gauge optimal harvest timing, it can be a useful indicator of when to begin measuring whole-plant DM content. Table 2 describes the kernel milk stages when the first samples should be collected. These values are based on numerous studies conducted in Canada and the northern USA, and reflect the stages when 90% of the samples collected were consistently too wet for ensiling in a given storage structure.

Under drought conditions or south of the upper tier of states in the USA, samples should be collected slightly earlier than the stages shown in Table 2. Corn reaches harvestable % DM at earlier kernel stages as you move south.

Table 2. Kernel milk stages when moisture sampling should begin for different storage structures.

How to Sample Fields

Collect 5 to 10 representative plants from the entire field. The plants should be uniformly chopped (using a cleaver, machete, chipper shredder, or silage chopper) and then mixed thoroughly to obtain a sample with representative grain to stover ratios for drying. Some farmers prefer sampling only 2 or 3 plants to reduce the chances of a non-representative grain to stover ratio. In this case, choosing representative plants is even more critical.

Moisture Measurement

Use one of the two methods described below to determine % DM of the sample. Each method requires a good scale that can measure in grams. These are available with the Koster Tester or postal digital scales can be ordered from NASCO or other mail order catalogs.

The accuracy of the % DM value obtained from either method will be largely determined by the amount of time and care taken in drying down and weighing the samples. This is especially true for corn silage where whole kernels and cob pieces can be difficult to dry completely without burning the leaf tissue.

a) Microwave Oven Method

- Clip or chop the corn plants into 2-5 cm (1-2 in) long pieces. Place a representative 100 to150 g sample on a paper plate and spread in a thin layer leaving an open area in the center (doughnut-shaped). Record the weight of the forage + paper plate: this is the initial wet weight.

- Place a 250 ml (8-ounce) glass of water (3/4 full) in the back corner of the microwave. Keep water amount somewhat constant during microwave use. You may need to replace the water in the cup with cold water to keep it from boiling over during the heating cycles. Heat the sample. Samples containing 50-75% moisture (25-50% DM) can be heated initially on high for 4 minutes. Samples with less than 30% moisture (over 70% DM) should be heated for only 2 to 3 minutes. Power of microwave ovens varies causing differences in drying times.

- If sample feels almost dry, weigh and record weight of the plate + sample. Stir the forage and reheat for another 60 sec if sample was originally 50-75% moisture or 30 sec if originally less than 35% moisture. Repeat heating and weighing until either weight changes by less than 1 to 2 g or forage begins to char. If any charring has occurred, use the previous weight for calculating the moisture content.

- The dry weight is the last weight recorded after which the sample does not decrease more than 1 to 2 grams and charring has not occurred.

- Calculate the % dry matter (DM): % DM = (Dry weight/initial wet weight) x 100

Example: The initial wet weight of plate + forage was 130 g and the final dry weight of plate + forage was 46 g. So, % DM = (46/130) x 100 = 0.354 x 100 = 35.4%

The % moisture content is calculated as follows: % moisture = 100 – % DM

Example: % moisture =100 – 35.4 = 64.6%

Notes: With a little experience, the microwave method can be run in less than 10 minutes. You may want to perform the procedure in the barn or work shed, because it does produce an odor.

Warning: Never leave microwave unattended while heating because samples can ignite!

b) Koster Tester Method

(available through Koster Crop Tester, Inc., 13477 Prospect Rd., Ste. 103C, Strongsville, OH 44136 or NASCO, www.nascofa.com)

- To weigh exactly 100 grams of sample, take the weight of the container (Koster basket) and add 100 grams of forage to the basket. Example: If the basket weighs 17 grams, the total weight is 117 grams

- Place the basket in the Koster dryer. Samples with 50-75% moisture will take more than an hour to dry. After one hour, record weight of sample at 5-15 minute intervals.

- Repeat steps 2 and 3 until weight becomes constant.

- The final dry weight (forage + basket), minus the basket weight, is the dry matter percentage.

Example: dry weight (forage + basket) is 52 g and basket weighs 17 g % DM = 52 –17 = 35% - To determine moisture content, subtract the % DM from 100.

Example: % moisture =100 – 35 = 65%

Predicting the Harvest Date

Once the target milk stage is reached and whole-plant % DM is determined, an average dry down rate of 0.5% unit per day can be used to estimate the number of days until harvest. For example, if a given field measures 30% DM at the early sampling date, and the target harvest DM content is 35%, then the field must gain an additional 5% units of DM requiring an estimated 10 days (5% units divided by 0.5 unit change per day).

This procedure provides only a rough estimate for the harvest date. Many factors affect the dry-down rate, including hybrid, planting date, general health of the crop, landscape position, soil type, and weather conditions. For example, in early planted fields or under hot and dry conditions, wholeplant % DM can increase at a rate of 0.8 to 1.0% unit per day. Fields should be monitored closely and whole-plant % DM determined again as the predicted harvest date approaches.

Spreading the Harvest Window

When planning harvesting operations, keep in mind the length of time required to harvest the field. Harvesting may need to start on the early side to ensure the field does not get overly dry by the time harvesting is complete. It is often better to err a little on the early (wet) side rather than to be too late unless kernal processors are used (see Processing Corn Silage section). Hybrid selection and planting date can be used to influence the timing and length of the harvest window.

Hybrid Selection

Select hybrids that vary in maturity to spread the risk of plant stress during pollination and to spread the harvest window. Greatest silage yields are usually achieved with full season hybrids. Hybrids can be 5 to 10 days later when used for silage than when used for grain.

Hybrids differ in rate of whole-plant drydown. Seed companies provide information on whole-plant dry-down rate for their hybrids. Recent studies in Canada demonstrated that hybrids with the leafy trait (with more leaves above the ear) dried down slower than standard types in some years (see Corn Growth and Development section).

Planting Dates

Staggering planting dates can help spread the harvest window. Full-season hybrids should usually be planted first to take advantage of their higher yield potential. Some producers like to plant an “ultra” short-season hybrid early to provide fermented feed during early fall. It is useful to keep records of planting dates and hybrid maturities for each field.

Summary

Harvest timing is a critical management decision to ensure corn will be ensiled at the proper dry matter content for effective fermentation and storage. The following steps will help producers harvest corn silage at the optimal time.

- Record hybrid maturity and planting date for each silage field.

- Record the silking date of each hybrid and field to be chopped for silage. Full dent of kernels will typically occur 35 to 42 days after silking.

- Once the kernel milk-line appears and begins to move (soon after full dent stage), sample and measure the wholeplant % DM of fields to be harvested for silage. Use a dry down rate of 0.5% unit per day to roughly predict when the field will be ready for the storage structure used.

- Sample the field again to determine whole-plant % DM prior to chopping.

Kernel stage not a reliable guide for timing harvest

Dry matter content of whole-plant corn varies with maturity. Historically, recommendations were to harvest corn silage when kernels were at the black layer stage but today’s hybrids are too dry at the black layer stage. Through the 1990’s, timing silage harvest based on the kernel milkline position was widely recommended. But recent studies in Canada and the USA have demonstrated that the position of the kernel milk-line, used alone, is not a reliable indicator for determining harvest timing. Geo-graphic location, planting date, hybrid selection, and weather conditions affect the relationship between kernel milk-line position and whole-plant DM content. In a Wisconsin study, 82% of the hybrids tested exhibited a poor relationship between kernel milk-line stage and whole-plant % dry matter. Thus, it is impractical for seed companies to develop hybrid-specific calibrations for kernel milk-line stage as a guide for silage harvest. Similarly, timing corn silage harvest based on a heat unit system is also unreliable.